Advanced Lightweight Metals and Alloys for Automobiles

Introduction

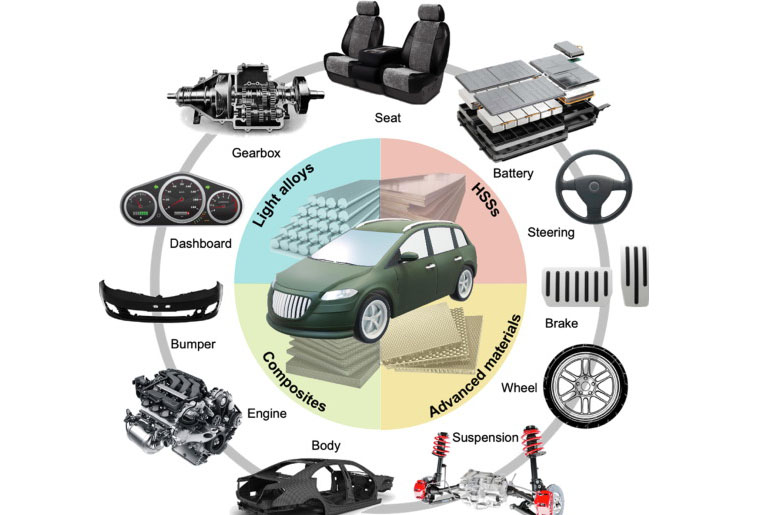

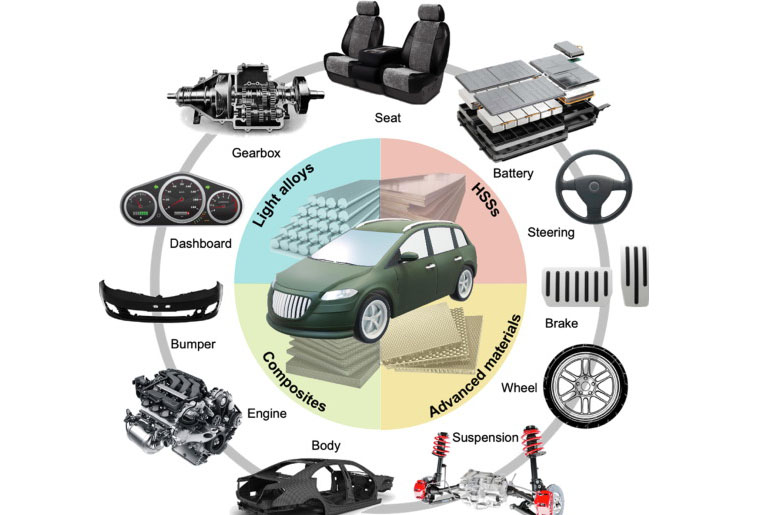

Lightweight metals and alloys have become one of the cornerstones of modern automotive engineering. Reducing vehicle weight directly improves fuel economy, reduces emissions, and enhances handling, acceleration, and braking. Over the past two decades, auto manufacturers have increasingly adopted advanced aluminum alloys, magnesium alloys, titanium alloys, and high-strength steels for body panels, chassis components, engine parts, and structural reinforcements. Let's learn about the uses of these advanced materials in automobiles.

Aluminum Alloys - The Workhorse of Lightweight Automotive Design

The reasons for this domination are the favorable strength-to-weight ratio, corrosion resistance, and versatility of aluminum alloys in lightweight vehicle design. Applications include a wide range from major engine blocks and cylinder heads to transmission cases, suspension components, body panels, and wheels. Today, many automakers employ aluminum-intensive architectures for SUVs, EVs, and performance sedans.

Common alloys include AA6xxx series for structural components and AA5xxx series for body panels and external parts; their mechanical performance is optimized for specific automotive needs through heat treatment and tempering.

Aluminum alloys have clear advantages, yet their limitations are worth noting as well: they are less stiff than steel, so often require thicker or reinforced sections, and their fatigue resistance may be lower under repeated loading if badly treated. Lastly, aluminum is more expensive than conventional steel, although techniques like high-pressure die casting can help to offset the cost.

Magnesium Alloys-Ultra-Lightweight Solutions

Magnesium alloys are one of the lightest of all the structural metals, having a density of about two-thirds that of aluminum. Some of the applications include steering wheels, seat frames, instrument panels, transmission housings, engine blocks, and gearboxes.

Typical examples of magnesium alloys are AZ91D (Al-Zn-Mn-Mg) for general die casting parts, and AM60 (Al-Mn-Mg) for structural parts that need higher ductility.

The magnesium alloy choice offers a number of attractive advantages-the extremely low density being the main one, which allows significant weight reduction. They also offer strong vibration-damping capabilities that help improve NVH performance along with excellent machinability, particularly in die-cast components.

Still, a number of limitations shape where magnesium can be used. Its corrosion resistance is lower than aluminum, meaning coatings or protective layers are often necessary. Magnesium also loses strength at higher temperatures, limiting its suitability in hot engine environments. While flammability during processing is a known concern, modern alloy design and tightly controlled manufacturing have greatly reduced this risk.

Titanium Alloys - High-Performance, High-Cost Components

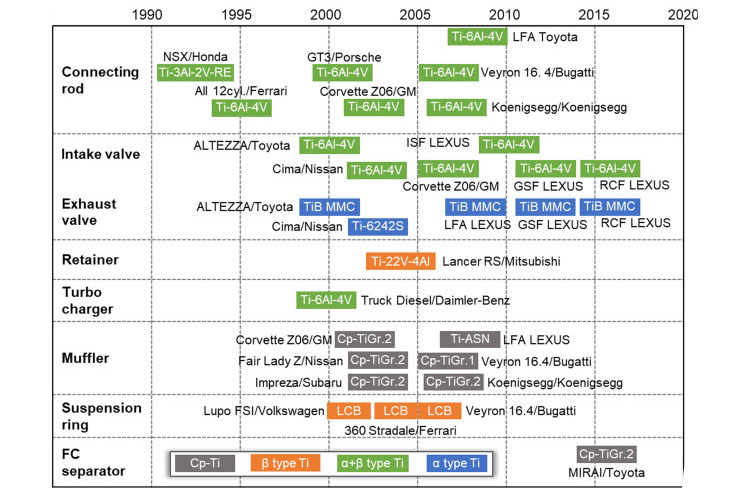

Due to their high strength-to-weight ratio, corrosion resistance, and high-temperature stability, these metal alloys are selectively used in high-performance and luxury cars. They usually find applications in the manufacture of exhausts, valves, connecting rods, suspension parts, and fasteners. In race and supercars, titanium unsprings reduce unsprung weight, enhance handling, and allow increased engine speed due to lower mass.

Commonly used automotive titanium alloys include Ti-6Al-4V, which is well balanced for strength, ductility, and corrosion resistance in high-performance applications.

However, there are some significant disadvantages to titanium. For one, it is far more expensive than aluminum or steel, which precludes its extensive application in higher-volume mainstream vehicles. It is also considerably harder to machine and form, further adding to manufacturing complexity and expense. If that is not enough, titanium is not as readily available in large sheet or plate format, which further limits its application to large structural automotive components.

Related reading: Advantages and Disadvantages of Titanium Used in the Automobile Industry

High-Strength Steels – Balancing Weight and Structural Integrity

HSS and UHSS have become indispensable for chassis components, safety cages, door beams, and suspension elements. In modern automotive design, HSS is often combined with lightweight metals to achieve structural rigidity without excessive weight. In particular, these steels play an important role in crash-critical areas of the vehicle where energy absorption and occupant safety are concerns.

Typical grades include AHSS dual-phase steels for body structures and martensitic steels for high-strength structural reinforcements.

High-strength steels present an excellent combination of performance and practicality. They provide good yield and tensile strength, thus supporting critical structural parts with strong crashworthiness in impact cases, ensuring excellent energy absorption. They are also much cheaper than titanium or advanced aluminum alloys and still available everywhere, easily fitting into the standard stamping, welding, and assembly processes.

That said, they do come with trade-offs. High-strength steels remain heavier than aluminum, magnesium, or titanium, which can limit weight-reduction gains. They also require proper coatings or galvanization to ward off corrosion-particularly in long-term automotive environments. Depending on the grade, forming or welding might be tough without specialized equipment or processing techniques.

Aluminum-Lithium Alloys - Next-Generation Lightweight Materials

Emerging in EV chassis, battery casings, and high-performance structural panels are aluminum-lithium alloys. Lithium decreases density and increases stiffness, thereby enabling engineers to maintain mechanical performance with thinner sections. These alloys are of particular interest for electric and hybrid vehicles since the reduction in weight directly leads to an improvement in range and efficiency.

Typical examples of alloys are Al-Li 2195 and Al-Li 2050, used in the aerospace sector but increasingly adapted for automotive applications.

Table 1: Properties of Common Lightweight Metals And Their Alloys for Automotive Applications

|

Material / Alloy |

Applications |

Key Advantages |

Limitations |

Common Grades |

|

Aluminum Alloys |

Body panels, engine blocks, wheels, chassis |

High strength-to-weight, corrosion resistance, recyclability |

Lower stiffness, higher cost |

AA5xxx, AA6xxx series |

|

Magnesium Alloys |

Steering wheels, seat frames, transmission housings |

Extremely low density, vibration damping, machinable |

Lower corrosion resistance, limited high-temp strength |

AZ91D, AM60 |

|

Titanium Alloys |

Exhausts, valves, connecting rods, fasteners |

High strength-to-weight, corrosion resistance, high-temp stability |

High cost, difficult to machine |

Ti-6Al-4V |

|

High-Strength Steels |

Chassis, safety cages, suspension components |

High strength, crashworthiness, cost-effective |

Heavier, corrosion requires protection |

AHSS, Martensitic steels |

|

Aluminum-Lithium Alloys |

EV chassis, battery casings, structural panels |

Low density, high stiffness, fatigue resistance |

Expensive, limited availability |

Al-Li 2195, Al-Li 2050 |

For more information, please check Advanced Refractory Metals (ARM).

Conclusion

Advanced lightweight metals and their alloys are playing key roles in modern automotive evolution: everything from improving fuel efficiency and EV range extension, to safety and driving dynamics.

While aluminum alloys remain the workhorse for a wide range of applications, magnesium alloys are pushing the limits of ultra-lightweight components. Titanium alloys are kept for high-performance applications and parts that are exposed to high temperature conditions, while high-strength steels keep on providing structural integrity and crash protection. New aluminum-lithium alloys promise an exciting future towards maximum efficiency in both electric and hybrid vehicles.

Reference:

[1] Wen Zhang, Jun Xu, Advanced lightweight materials for Automobiles: A review, Materials & Design, Volume 221, 2022, 110994, ISSN 0264-1275.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}