A Comprehensive Handbook of LTS Materials

Superconductivity, where electric resistance disappears, has revolutionary potential in a broad range of applications from medicine to energy and ultra-high energy physics. Although high-temperature superconductors (HTS) are often newsworthy, low temperature superconductors (LTS) remain the workhorse in most real-world applications because they are mature, proven, and well characterized in cryogenic conditions.

Let's study the key concepts of LTS, which has principal materials like Nb₃Sn, Nb₃Al, and NbTi, and discusses their processing methods and application environment.

[1]

[1]

What Are Low Temperature Superconductors?

Low temperature superconductors are those that exhibit a superconducting state at temperatures typically below 20 K. Unlike HTS materials such as YBCO (which work at liquid nitrogen temperatures), LTS materials must be cooled in liquid helium (4.2 K) or cryocoolers in order to become superconducting.

LTS materials are categorized based on their critical temperature (Tc), critical magnetic field (Bc2), and critical current density (Jc). These define the operating parameters under which a superconductor can carry current without resistance. LTS materials are advantageous in the sense that they can carry large electrical currents, offer stable and uniform operation in high magnetic fields, and have mature fabrication processes enabling their large-scale reliable production.

Major Low Temperature Superconducting Material Types

1. Niobium-Titanium (NbTi)

NbTi is the most widely utilized LTS material, especially in commercial applications. It was initially produced in the 1960s and remains the standard choice for systems up to 10 T magnetic fields due to the fact that it possesses:

• Tc ≈ 9.2 K,

• Bc2 ≈ 14.5 T,

• High ductility, which makes it convenient to produce in wire form.

Its mechanical flexibility combined with superconducting characteristics render it an optimum selection for MRI magnets, cryogenic cables, and all-purpose superconducting magnets.

Further reading: Niobium-Contained Superconducting Materials and Their Applications

2. Niobium-Tin (Nb₃Sn)

Discovered earlier than NbTi but harder to manufacture, Nb₃Sn offers superior performance at high fields:

• Tc ≈ 18.3 K,

• Bc2 up to 30 T,

• Elevated Jc values at fields >10 T.

However, Nb₃Sn is a hard intermetallic compound and requires sophisticated fabrication methods such as wind-and-react or react-and-wind methods. It is extensively utilized in fusion reactors (e.g., ITER), particle accelerators, and NMR systems over 1 GHz.

3. Niobium-Aluminum (Nb₃Al)

Nb₃Al is a candidate to replace Nb₃Sn with comparable superconducting behavior and improved strain tolerance:

• Tc ≈ 18.0 K,

• Bc2 up to 29 T,

• Greater thermal stability under mechanical stress.

Even though these advantages, its production requires advanced rapid-heating/quenching (RHQ) techniques, limiting commercialization. It is currently being pursued for use in the next generation of accelerators and magnetic fusion devices.

4. Other Materials

LTS research has also explored:

V₃Ga and V₃Si, with high critical fields but not much use due to brittleness and fabrication challenges.

MgB₂, though conventionally considered as a "mid-temperature" superconductor with Tc of 39 K, is capable under some low-temperature conditions and can offer cost-effective alternatives for specific applications.

Processing and Fabrication of LTS Materials

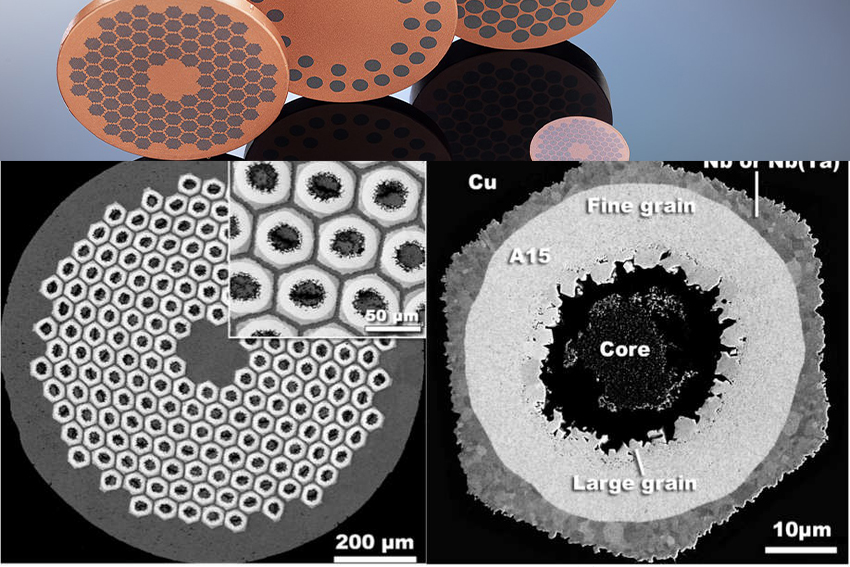

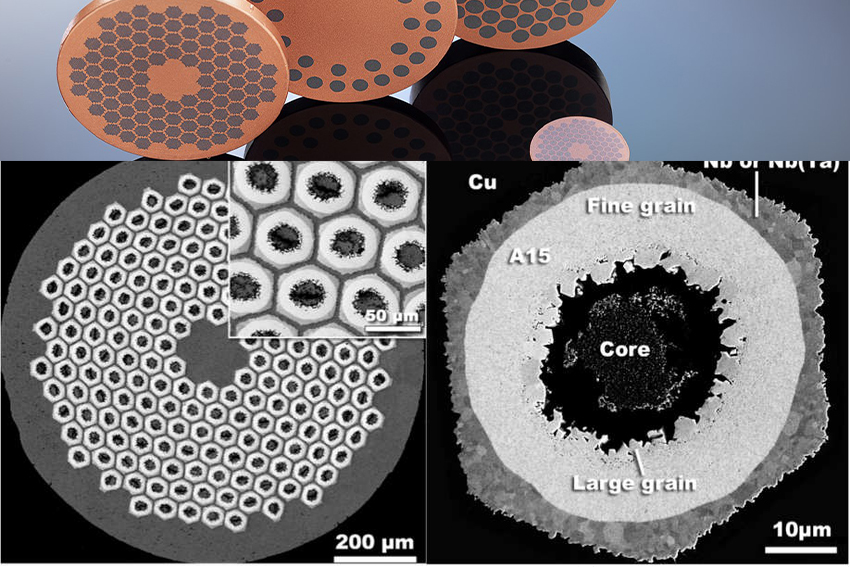

Processing and fabrication of LTS materials entail the creation of filaments or wires that are capable of carrying high current densities and are capable of withstanding cryogenic conditions and electromagnetic stresses.

- NbTi wires are fabricated by conventional metallurgical processes such as cold working and extrusion, with the superconducting filaments encapsulated in a copper stabilizer. The result is flexible high-current conductors.

- Nb₃Sn, due to its brittleness, requires the use of advanced processing methods like the bronze method, the internal tin method—currently the most popular—and the powder-in-tube (PIT) technique, where there may be precise control in intricate designs.

- For Nb₃Al, the most important process is quenching and rapid heating (RHQ) and subsequent annealing to form the A15 superconducting phase, which leaves grains strengthened and with enhanced mechanical strength, though the process is challenging to upscale industrially.

Key Applications of LTS Materials

Medical Imaging

Magnetic resonance imaging (MRI) systems use NbTi-based magnets heavily to generate strong and stable magnetic fields, typically up to 3 T, to enable diagnostic images of high resolution.

High Energy Physics

Particle accelerators such as the Large Hadron Collider (LHC) employ NbTi and Nb₃Sn superconductors in precise beam steering and focusing in extremely magnetic field conditions.

Fusion Energy

ITER toroidal field coils apply Nb₃Sn to confine plasma in fusion reactors, in fields over 12 T, where stability and strength are of critical importance.

Research Instruments

Techniques such as Nuclear Magnetic Resonance (NMR) and Electron Spin Resonance (ESR) depend on LTS magnets to maintain ultra-stable magnetic conditions for accurate scientific measurement.

Power and Grid Technologies

LTS conductors, especially those of NbTi and MgB₂ types, are being designed for use in superconducting power cables and fault current limiters with the aim of increasing grid efficiency and reliability.

Nb₃Sn vs Nb₃Al vs NbTi vs More

|

Property |

NbTi |

Nb₃Sn |

Nb₃Al |

MgB₂ |

|

Tc (K) |

~9.2 |

~18.3 |

~18.0 |

~39 |

|

Bc2 (T @ 1.8 K) |

~14.5 |

~26–30 |

~29 |

~20 |

|

Mechanical Flexibility |

Excellent |

Poor (brittle) |

Moderate |

Good |

|

Fabrication Complexity |

Low |

High |

Very High |

Moderate |

|

Industrial Maturity |

High |

High |

Emerging |

Emerging |

|

Application Field |

MRI, cables |

Fusion, accelerators |

Accelerators, fusion |

Power systems |

For more information and tech support, please check Advanced Refractory Metals (ARM).

Conclusion

Low-temperature superconducting materials such as NbTi, Nb₃Sn, and Nb₃Al form the mainstay of current superconducting technology. NbTi possesses unmatched ductility and ease of fabrication and is thus ideal for medical and industrial uses. Nb₃Sn is useful for high-field applications at the cost of mechanical vulnerability. Nb₃Al is an attractive mid-point alternative but hangs on to the development of future processing technological advances for widespread application.

Reference:

[1] Luca Bottura(CERN), Arno Godeke(LBL, Berkeley) (2012). Superconducting materials and conductors: Fabrication and limiting parameters. Rev.Accel.Sci.Tech. 5 (2012) 25-50.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}