5 Aerospace Applications of Iridium

Iridium may be rare and notoriously difficult to work with, but in the world of aerospace, it has earned a place among the most indispensable materials. Known for its exceptional corrosion resistance, high melting point, and stability under extreme conditions, iridium plays a vital role in aerospace applications where durability and reliability are paramount.

Here list five key aerospace applications of iridium.

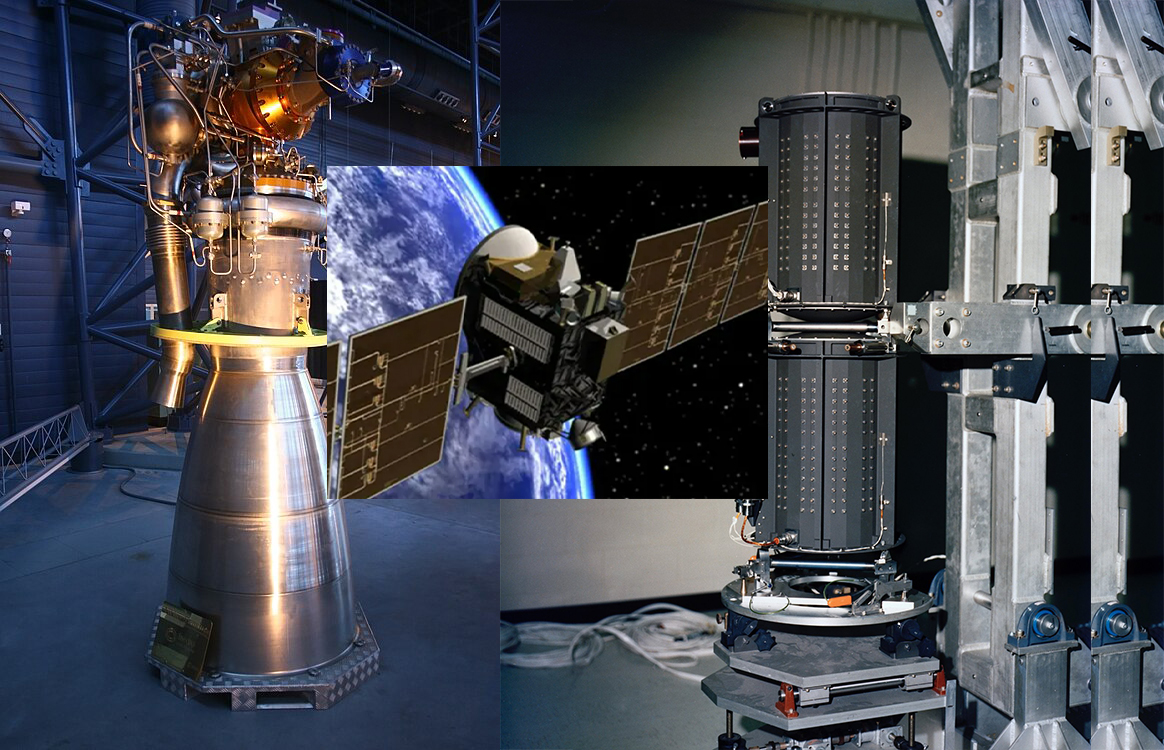

1. Rocket Engine Components

In propulsion systems, where metal parts must endure searing temperatures, violent chemical reactions, and repeated thermal cycling, iridium’s robustness is unmatched. One of its most notable uses is in combustion chambers and nozzle linings of rocket engines, particularly for small thrusters or engines using highly reactive propellants.

Iridium resists oxidation and erosion better than most metals—even at temperatures exceeding 2,400°C—making it ideal for lining areas exposed to direct combustion. This is critical in solid rocket motors and certain liquid bipropellant engines, where conventional metals would degrade rapidly. NASA and other space agencies have relied on iridium-lined components to ensure longer service life and more consistent performance during burns.

Because iridium can withstand continuous operation in extreme thermal environments without significant material loss, it helps improve engine longevity and reduces the frequency of part replacements—an essential benefit when repairs in space are impossible.

Further reading: Iridium Uses & Properties

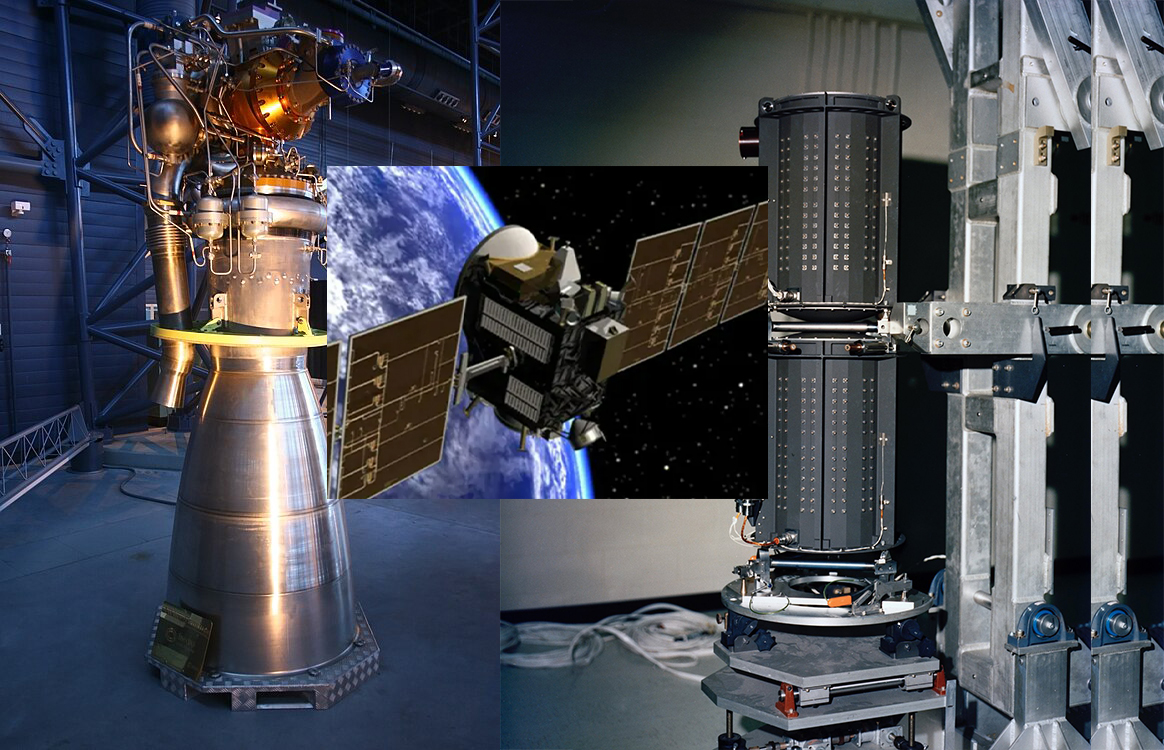

2. Catalyst Beds in Satellite Thrusters

Small spacecraft thrusters, such as those found in satellites and space probes, commonly use hydrazine as a monopropellant. To decompose hydrazine into thrust-producing gases, the propellant passes over a catalyst bed. Iridium-coated materials are crucial in this context due to their thermal stability and resistance to deactivation.

Iridium serves as the catalytic layer on alumina or metal substrates, initiating the exothermic decomposition of hydrazine into nitrogen, hydrogen, and ammonia. This process produces rapid, clean combustion necessary for precise attitude control and station keeping.

These iridium-coated catalyst beds are central to the operation of reaction control systems (RCS) and orbital maneuvering thrusters, especially on long-term missions. Without the reliability offered by iridium’s inert and heat-resistant nature, satellites would face increased risks of thruster failure, jeopardizing mission goals.

3. Thermocouples and High-Temperature Sensors

Measuring temperature in aerospace environments often demands materials that can withstand extremes far beyond the range of standard sensors. Iridium–Rhodium thermocouples are among the few solutions capable of providing accurate temperature data above 1,700°C.

These thermocouples—especially Type B (Platinum 6% Rhodium vs. Platinum 30% Rhodium)—frequently incorporate iridium or iridium alloys for improved lifespan and signal stability. In rocket engine testbeds, re-entry vehicle heat shield evaluations, and hypersonic flow simulations, such sensors are indispensable.

By delivering precise thermal feedback during critical operations, iridium-containing thermocouples help aerospace engineers fine-tune combustion profiles, validate thermal protection systems, and ensure that engine components remain within safe operating limits.

4. Radioisotope Thermoelectric Generators (RTGs)

One of the most iconic uses of iridium in space exploration is in radioisotope thermoelectric generators, or RTGs. These devices convert heat from the decay of radioactive materials—typically plutonium-238—into electrical power for long-duration space missions.

Iridium is used to encapsulate the plutonium fuel pellets within RTGs, providing a high-strength, corrosion-resistant containment barrier. This iridium cladding must perform reliably over decades, protecting both the spacecraft and any potential Earth re-entry scenarios from radioactive contamination.

NASA's Voyager, Cassini, and Curiosity missions all employed RTGs with iridium containment systems. These systems not only provide consistent power far from the Sun but also ensure safety, thermal shielding, and physical integrity even in the event of a catastrophic launch failure.

Iridium’s unique combination of impact resistance, high melting point, and chemical inertness makes it the metal of choice for this life-critical function.

5. Optical and Infrared Mirror Coatings

In modern aerospace optics, especially in space telescopes, Earth observation satellites, and infrared imaging systems, iridium is increasingly used as a mirror coating. Its reflective properties across the infrared and visible spectrum, combined with its exceptional durability, make it an ideal choice for demanding optical applications.

Unlike silver or aluminum, iridium is far less reactive, meaning it doesn't degrade easily in space. It can maintain high reflectance over long durations without requiring protective overcoats, even in the presence of atomic oxygen and solar radiation.

For example, telescopes designed to observe the universe in the mid-infrared range benefit from iridium’s ability to reflect longer wavelengths efficiently while resisting pitting or erosion caused by the harsh space environment. Additionally, iridium-coated mirrors maintain their shape and reflective quality even after exposure to launch vibrations and orbital debris.

Conclusion

In aerospace engineering, where conditions push materials to their limits, iridium offers a rare mix of performance and endurance. From initiating thruster reactions to protecting radioactive power sources, its roles span propulsion, power, sensing, and optics—every one of them mission-critical. For more capillary tubes, please check Advanced Refractory Metals (ARM).

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}