What Refractory Metals Are Commonly Used in Vacuum Systems?

What Refractory Metals Are Commonly Used in Vacuum Systems?

Refractory metal refers to metals with a certain reserve and a melting point that is higher than 1650 ℃. Refractory metals include tungsten, tantalum, molybdenum, niobium, hafnium, chromium, vanadium, zirconium, and titanium. Rhenium also has a high melting point, but its reserves are too small, and most of it is used in high-temperature alloy parts for jet engines. In this article, we will take a look at what refractory metals are commonly used in vacuum systems.

Refractory Metals Are Commonly Used in Vacuum Systems

Refractory Metals Are Commonly Used in Vacuum Systems - 1. Tungsten

Tungsten is the commonly used refractory metal with the highest melting point. Tungsten is not only hard but also chemically stable. Tungsten's hardness and high melting point make it difficult to process, however, the welding of flake or filamentous tungsten is easy, so tungsten is often used for electron emission filament, the cathode of the X-ray tube, spring element, high-temperature thermocouple, steaming plate of the furnace and welding electrode, etc. in vacuum system.

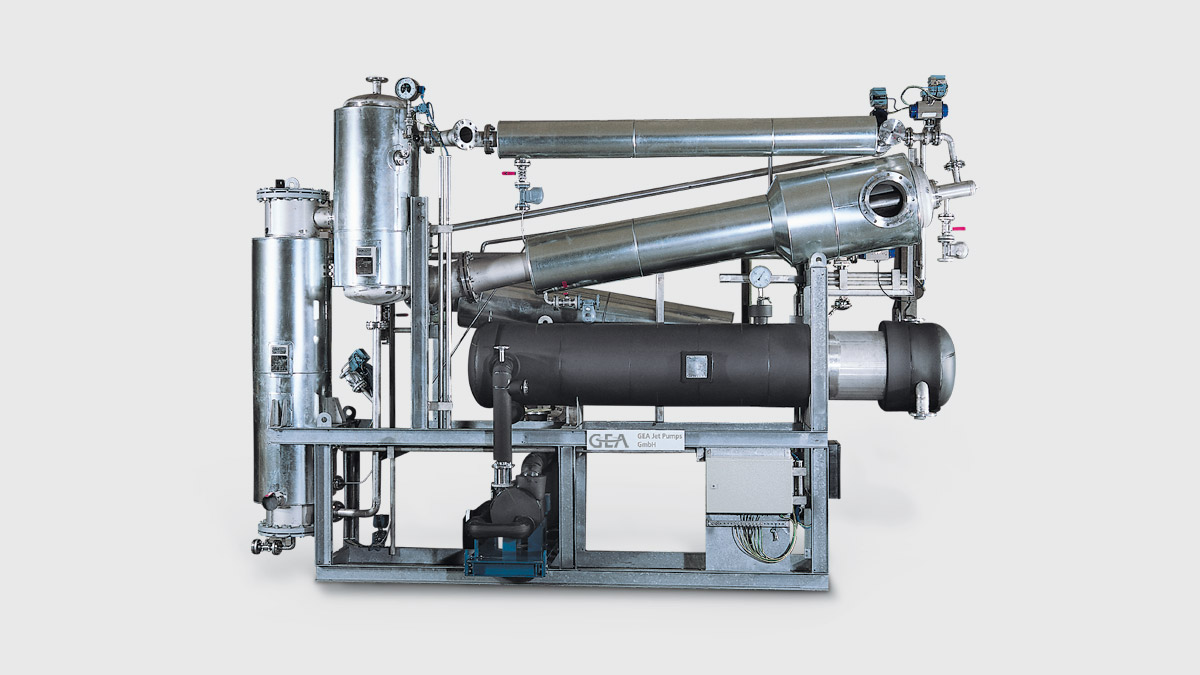

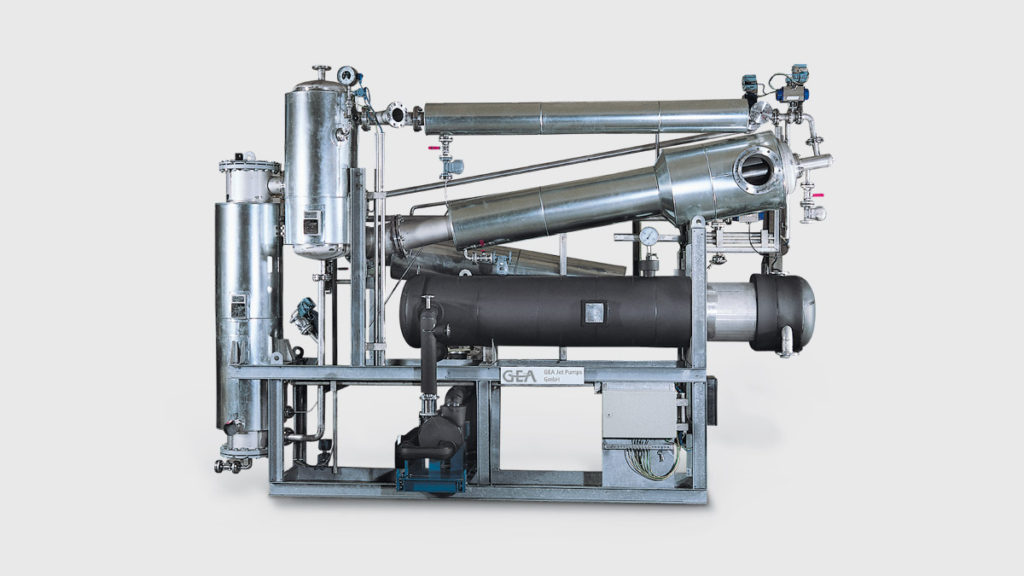

Vacuum system

Refractory Metals Are Commonly Used in Vacuum Systems - 2. Tantalum

Tantalum is a lightweight but high-strength refractory metal, it's melting point temperature is 2996 ℃. Chemically, tantalum has excellent corrosion resistance and does not react to water, chromic acid, nitric acid, sulfuric acid, and hydrochloric acid under cold and hot conditions.

However, it is soluble in hydrofluoric acid, fluoride solution, and oxalic acid. Meanwhile, it can combine with hydrogen to form the hydride, which damages metal properties and causes brittleness. Tantalum can absorb most of the residual gases except the inert gases in the vacuum system.

In vacuum applications, tantalum is also a good electron emitter (between molybdenum and tungsten) and is often used in HCD ion plating equipment to make hollow hot-cathode guns to generate electron beams.

Besides that, tantalum can be used as the getter, tantalum crucible, and evaporator under high vacuum and high temperature.

Refractory Metals Are Commonly Used in Vacuum Systems - 3. Molybdenum

Molybdenum is a refractory metal with high hardness, no magnetism, and stable chemical properties. Molybdenum is oxidized at high temperatures, while it is stable in air or water at normal or low temperatures.

In vacuum application, molybdenum will use heat treatment or add niobium to improve tensile strength. Molybdenum is commonly used in the form of rods, cylinders, bolts, nuts, and heating coils, and it can also be used as the sealing of glass and metal, the evaporating dish in the vacuum electric furnace, and the electrode of various vacuum devices.

Refractory Metals Are Commonly Used in Vacuum Systems - 4. Niobium

Niobium is a refractory metal with large strength and small specific gravity. The properties of niobium are similar to those of tantalum; however, it has a low melting point and a higher vapor pressure than tantalum, so it is rarely used as a thermoelectric emitter. Because of its strong affinity, niobium can be used as an inhaler, especially a high-temperature getter.

In a vacuum system, niobium can also be used as a structural material, as well as for electric welding or electron beam welding. It is added as an additive to some stainless steel to prevent intergranular corrosion caused by carbon. Moreover, niobium and other refractory metals can be seen in the electric body and heat shield of the heating device in the vacuum equipment.

Conclusion

Thank you for reading our article - What Refractory Metals Are Commonly Used in Vacuum Systems? and we hope you've enjoyed it. If you want to know more about refractory metals, you can visit Advanced Refractory Metals for more information. We provide our customers with high-quality refractory metals at a very competitive price.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}