What Are the Special Refractories Widely Used in Modern Industry?

What Are the Special Refractories Widely Used in Modern Industry?

Special refractories mainly include high melting point oxides, high melting point non-oxides, and the derived composite compounds, cermet, high-temperature coating, high-temperature fiber, and reinforcing materials. Among them, non-oxides with a high melting point are usually called refractory compounds, which also include carbides, nitrides, borides, silicides, and sulfides.

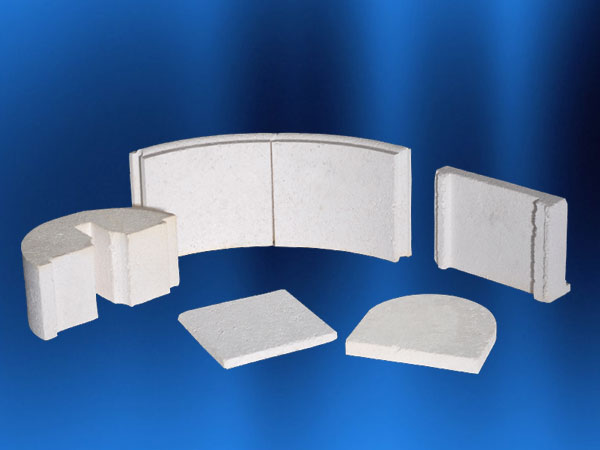

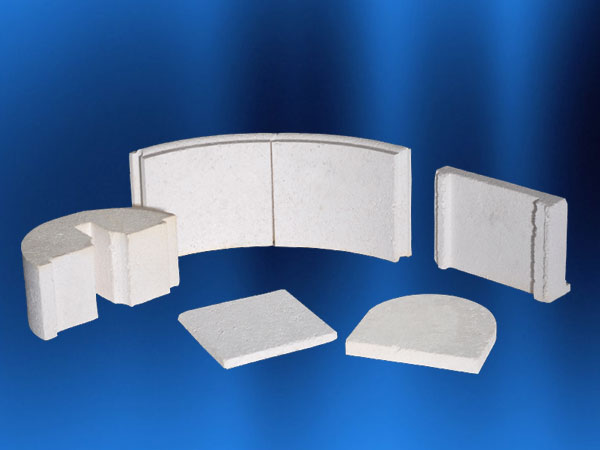

Special Refractories

Although the cost of special refractories is relatively high, they are indispensable and irreplaceable products in many industrial sectors due to their excellent properties.

Special refractories replace other products in many key parts in many new technologies and fields, which can greatly improve service life and significantly increase economic benefits. The classification of special refractories can be roughly divided into the following five aspects according to the different properties of raw materials and products.

- Oxides with a high melting point and their composites;

- Refractory compound materials (carbides, nitrides, borides, silicides, etc.) and their composites;

- The composite material of oxides and refractory metals with a high melting point (cermet);

- High-temperature amorphous material and inorganic coating;

- High-temperature fiber and its reinforcing material.

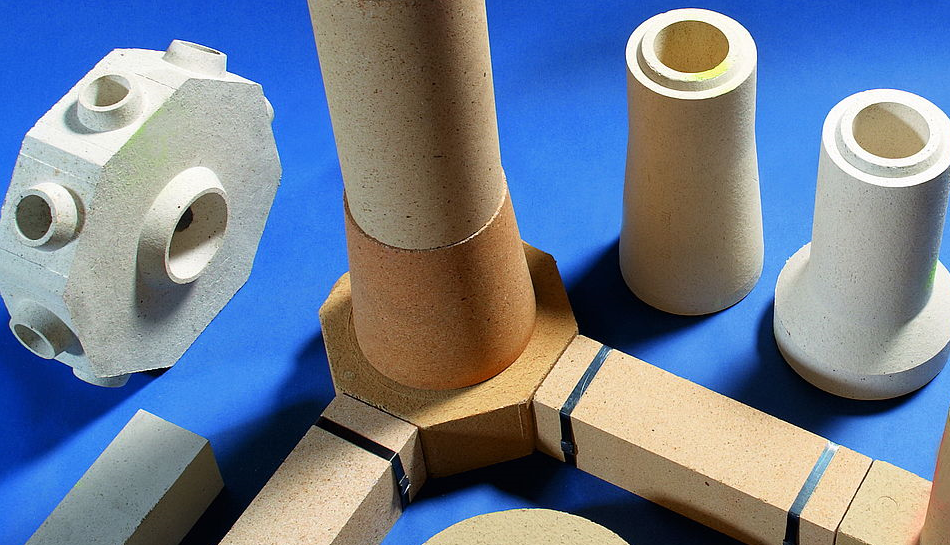

Alumina (Corundum)

Corundum brick with high purity, high density, and high performance has been widely used in the large blast furnace and the ladle of the steel plant and achieved good results. It is the best lining material for the second-stage furnace and gasifier of a large ammonia synthesis plant (300,000t) and the cracking furnace of 300,000t ethylene projects.

Alumina

Besides, corundum brick with high thermal stability is the preferred lining material for various ultra-high-temperature furnaces such as special refractories and products firing furnaces, molybdenum wire furnaces, diffusion furnaces, ceramic metallization furnaces, molybdenum silicide electric furnaces and so on.

Alumina hollow ball products and alumina fiber products belong to high-temperature energy-saving products, which are ideal lining materials for energy saving and consumption reduction because of their small volume density, and low thermal conductivity.

Alumina precision ceramics can be made into crucibles and gaskets, high-temperature furnace tubes, thermocouple protection tubes, and insulating porcelain tubes for smelting or purifying non-ferrous metals and rare and precious metals, etc.

Magnesium Oxide (Magnesia)

Magnesia is an alkaline refractory with high load softening temperature and low creep. While its melting point can reach 2800 ℃, it is easy to volatilize in a reducing atmosphere, so the maximum service temperature can only be 2000 ℃.

Magnesium oxide

Magnesium oxide is a good structural material for ultra-high temperature furnaces, as well as a good lining material for industrial frequency furnaces, intermediate frequency furnaces, and high-frequency heating furnaces.

Magnesium oxide ceramic products can be made into non-ferrous, rare metals, and precious metals smelting, purification of magnesium oxide crucible, high-temperature furnace tubes, ultra-high temperature tungsten-rhenium thermocouple protection tube, and insulation porcelain beads.

Zirconia

Due to its high-temperature chemical stability, the maximum service temperature of zirconia can reach 2400 degrees, which can be used as a vacuum furnace, molybdenum wire furnace, gas furnace, medium and high-frequency electric furnace, single crystal furnace, and other high-temperature lining materials.

Zirconia hollow balls and zirconia fiber products are the most advanced heat preservation and energy-saving lining materials in the oxide. The high-temperature zirconia ceramics can be made into crucibles for smelting nonferrous and rare metals, as well as high-temperature furnace tubes and thermocouple protection tubes.

Besides, zirconia special refractories can also be made into high-temperature electric furnace heating bodies, thermistors, gas sensors, spray coating and castable refractory, and other amorphous.

Zirconia

Other Oxides

Other special oxide refractories mainly include beryllium oxide (BeO), calcium oxide (CaO), and silicon oxide (SiO2).

- Beryllium Oxide

Beryllium oxide is a kind of alkaline special refractory, especially those with high thermal conductivity, good thermal shock resistance, and low electrical conductivity. It has good nuclear properties, such as strong neutron deceleration ability and X-ray penetration, but it is restricted in production and application due to its great toxicity.

Beryllium oxide can be used to make containers for smelting rare metals and high-purity metals Be, Pt, and V, neutron moderator and anti-radiation material for atomic reactors, and high frequency, insulation, and heat dissipation devices for the electronics industry.

- Calcium Oxide

Calcium oxide is also alkaline special refractory. Although it has a high melting point, it is easy to hydrate and produce pulverization, which is greatly restricted in application. The products of calcium oxide can be used as special refractories for melting platinum, ultrapure uranium, and nonferrous metals crucible and jet metallurgy.

- Silicon Oxide

Silicon oxide has an extremely low linear expansion coefficient and excellent thermal shock resistance. Fused quartz products can be used as the liner for conveying pipe, valve, and pump in nonferrous metal smelting.

In the chemical industry, quartz is used as the lining material for acid-resistant and corrosion-resistant containers and reactors, while it is used as the melting pool brick, arch flow ring, plunger, and hot repair material in the glass industry.

Conclusion

Thank you for reading our article and we hope it can help you to have a better understanding of the special refractories widely used in the modern industry. If you want to know more about special refractories or other refractory metals, we advise you to visit Advanced Refractory Metals (ARM) for more information.

Headquartered in Lake Forest, California, America, Advanced Refractory Metals is a top manufacturer & supplier of refractory metals across the world, providing customers with high-quality refractory metals such as tungsten, molybdenum, tantalum, rhenium, titanium, and zirconium at a very competitive price.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}