Tungsten Alloys and Their Use in Aerospace

Tungsten alloys are noted for their high density, strength, and resistance to wear. Thus, they are used in aerospace and beyond. This article covers their types and detailed applications in aerospace.

What Are Tungsten Alloys?

Tungsten alloys are created to improve the material’s performance in specific applications. Tungsten on its own is a heavy dense metal known for its high melting point and toughness. But this metal can break too for some jobs. By mixing it with nickel, iron, copper, or rhenium, we can tweak tungsten's traits to fit specific needs.

Types of Tungsten Alloys

There are several types of tungsten alloys. Here’s a list of the most commonly used tungsten alloys:

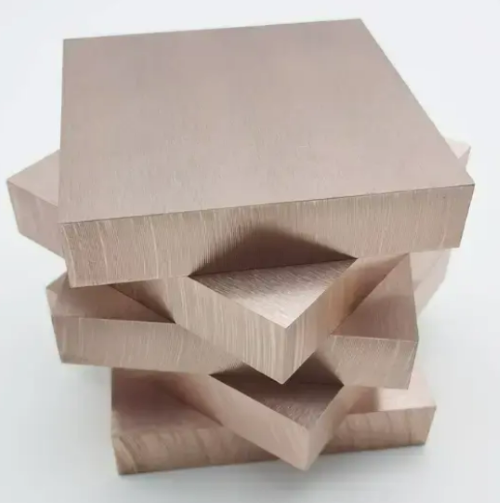

--W-Ni-Fe Alloy (Tungsten-Nickel-Iron)

- High Density (17-18.5 g/cm³) – Useful for radiation shielding and counterweights.

- High Strength & Ductility – Better than pure tungsten due to the Ni-Fe binder.

- Good Machinability – Can be cut, drilled, and shaped more easily than pure tungsten.

- Excellent Corrosion Resistance – Resists oxidation and chemical degradation.

- High Melting Point – Maintains structural integrity under extreme heat.

- High density (16–18 g/cm³) – Useful for counterweights and radiation shielding.

- Non-magnetic – Suitable for sensitive electronic and aerospace applications.

- Good machinability – Easier to process than pure tungsten.

- Moderate strength and ductility – Better than pure tungsten but lower than W-Ni-Fe alloys.

- High Melting Point (W: 3,422°C, Re: 3,186°C)

- Enhanced Ductility (reduced brittleness compared to pure tungsten)

- Superior Creep Resistance (ideal for high-stress, high-temperature environments)

- Excellent Electrical and Thermal Conductivity

Summary Table: Types of Tungsten Alloys

|

Alloys |

Used |

Properties |

Specific Data |

|

W-Ni-Fe |

Counterweights, radiation shielding |

High density, good strength, radiation shielding |

Density: ~17 g/cm³, Melting Point: ~3,400°C |

|

W-Ni-Cu |

Thermal conductivity, heat dissipation |

Good thermal conductivity, medium density, good machinability |

Density: ~17 g/cm³, Thermal Conductivity: ~150 W/m·K |

|

W-Re |

High-temperature uses, aerospace engines |

Great strength at elevated temperatures |

Density: ~18 g/cm³, Melting Point: ~3,370°C, Tensile Strength: ~900 MPa |

|

W-C |

Abrasive parts |

Quite hard, wear and erosion resistance |

Hardness: ~2500 HV, Density: ~15 g/cm³ |

For more information, please check Advanced Refractory Metals (ARM).

Why Tungsten Alloys Are Important to the Aerospace Industry

Aerospace is a demanding industry. Parts are subjected to high-speed motion, rapid changes in temperature, and high levels of stress. Tungsten alloys are used to make aerospace components to stand these conditions.

- High Density and Strength: A small volume of tungsten alloys can provide a large amount of mass. Therefore, they are perfect for counterweights and radiation shielding.

- Wear Resistance and Corrosion Resistance: With these features, they perform well even in the high-altitude and high-speed conditions found in aerospace.

- Thermal Conductivity: These alloys can spread heat well. That’s quite important for aerospace engines.

- Thermal Conductivity: These alloys can dissipate heat efficiently. That’s quite important for aerospace engines. Heat dissipation is vital for preventing engine components from overheating

By using tungsten alloys, aerospace manufacturers can produce parts that not only perform under extreme conditions but also last longer and require less maintenance.

How Tungsten Alloys Are Used in Aerospace

Tungsten alloys are used in multiple components within aerospace.

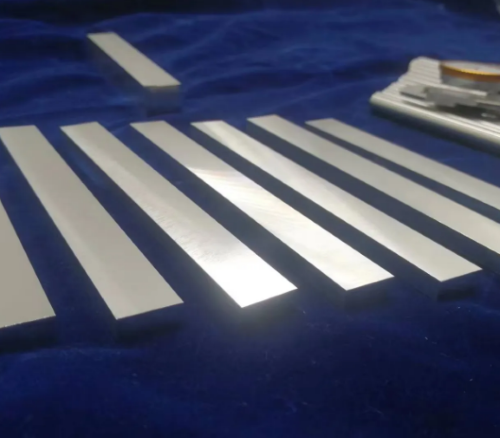

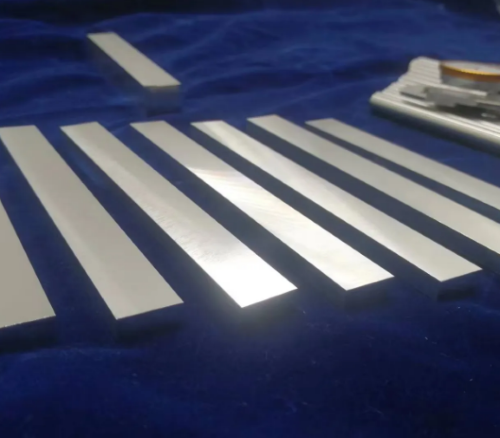

- Counterweights:

Plane makers often use tungsten alloys W-Ni-Fe alloys, as counterweights. These weights help balance different parts of the plane, like control surfaces or landing gear. W-Ni-Fe alloys are heavy (about 17 g/cm³), so they are perfect for making counterweights.

- Radiation Shields:

In space travel, radiation can be dangerous. Tungsten alloys block radiation well. They can guard delicate electronics and astronauts from harmful rays. The W-Ni-Fe alloy, with its melting point around 3,400°C, is particularly suitable for these applications.

- Engine Components:

Tungsten alloys like W-Re (tungsten-rhenium) are commonly used in high-temperature components within aerospace engines. There are turbine blades and combustion chambers. W-Re alloys offer excellent strength even under extreme heat. They can maintain the performance and longevity of engine components exposed to high thermal stress.

- Heat Management:

W-Ni-Cu alloys are used for heat dissipation in aerospace engines. These alloys prevent overheating. With a thermal conductivity of approximately 150 W/m·K and a density of around 17 g/cm³, W-Ni-Cu alloys are highly effective in maintaining temperature control in critical engine systems.

Conclusion

In a word, tungsten alloys are important to the aerospace industry. With high density, strength, heat resistance, they find various uses in aircrafts and space crafts.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}