The Biocompatibility of Titanium Alloys: Achievements and Developments

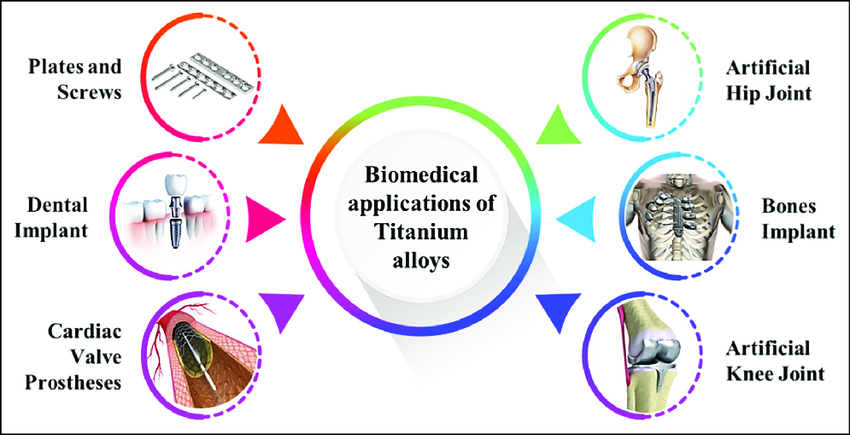

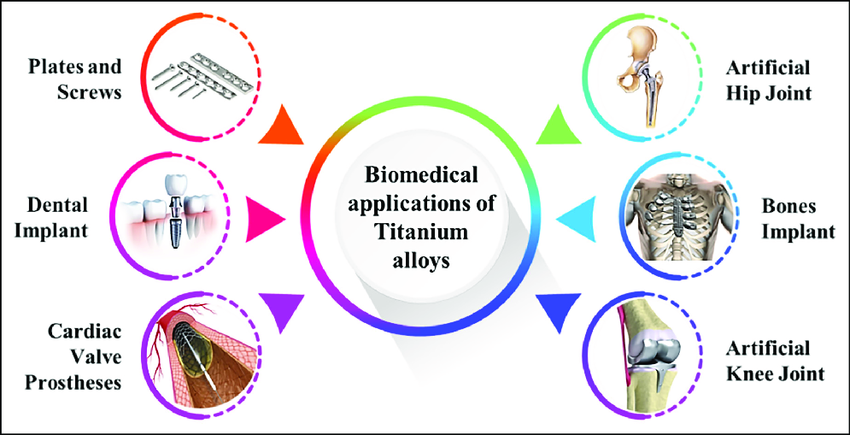

Titanium alloys and titanium have emerged as the cornerstone of modern implant technology due to their superior biocompatibility, mechanical stability, and corrosion resistance. Titanium has far surpassed most other metallic biomaterials in everything from dental appliances to orthopedic implants. Below list some of the most common examples and cases.

The Biocompatibility of Titanium Alloys

Titanium alloys' biocompatibility is partly a consequence of their passive oxide surface film. Titanium spontaneously forms a thin but hard film of titanium dioxide (TiO₂) when it is exposed to air or to physiological fluids. The film is chemically stable, nontoxic, and highly adherent. The layer avoids corrosion of the metal, blocks harmful ion release, and allows bone and soft tissue interaction.

Titanium is also bioinert, i.e., it does not produce extreme inflammatory reactions or immune rejection. Significantly, it supports osseointegration—the direct structural implantation between the surface of the implant and living bone. This property provides long-term stability in orthopedic and dental applications, and thus titanium implants are highly reliable.

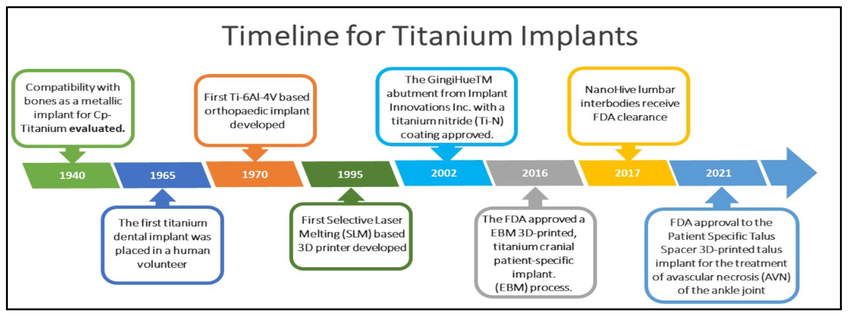

Fig. 1 A brief history of the development of titanium implants for biomedical devices. [1]

The Greater Biocompatibility of Beta Titanium

Beta titanium alloys are a new generation of titanium-based biomaterials designed to address the shortcomings of conventional alloys like commercially pure titanium (CP-Ti) and Ti-6Al-4V. Elastic modulus is one key improvement. Although CP-Ti and Ti-6Al-4V share a Young's modulus of ~100–115 GPa, beta titanium alloys have values of 55–65 GPa—much closer to that of human cortical bone (10–30 GPa). This helps to reduce stress shielding, which is a common cause of loosening of the implant due to resorption of bone due to mechanical mismatch.

Beta alloys also exhibit increased mechanical strength, better corrosion resistance, and higher fatigue life. Their non-toxic alloying elements also result in higher biocompatibility.

Further reading: 3 Types of Titanium Alloys & Their Uses

Notable Beta Titanium Alloys in Biomedical Applications

- Ti-29Nb-13Ta-4.6Zr (TNTZ) is a low elastic modulus beta titanium alloy with an elastic modulus of approximately 60 GPa, in addition to having improved corrosion resistance and good bone cell compatibility.

- Ti-35Nb-7Zr-5Ta exhibits enhanced osseointegration through bone cell adhesion and proliferation and is therefore suitable for applications where rapid osseointegration is to take place. Another alloy,

- Ti-24Nb-4Zr-7.9Sn, highly valued owing to its high fatigue resistance and biological inertness, is an excellent choice for load-bearing orthopedic implants.

Together, these alloys have delivered promising outcomes in in vitro and in vivo tests, such as enhanced bone tissue integration and reduced inflammatory reactions compared to traditional titanium alloys.

Other Biocompatible Titanium Alloys

While beta titanium alloys have become popular, other metal and titanium systems are still the cornerstones.

1. Ti-6Al-4V (Alpha-Beta Alloy):

The most widely used titanium alloy for implants, Ti-6Al-4V offers an excellent balance of strength, corrosion resistance, and machinability. Concerns regarding cytotoxicity due to vanadium and aluminum ions, especially with long-term exposure, have been present.

Further reading: Titanium Alloy Ti-6Al-4V: Features, Manufacturing, and Uses

2. Ti-Nb, Ti-Zr, Ti-Mo Alloys:

Toxic element-free systems are being explored as alternatives to vanadium and aluminum. For example, Ti-Nb alloys have high biocompatibility with lower elastic moduli and are thus suited for orthopedic applications.

3. Porous Titanium Structures:

Fabricated using additive techniques such as selective laser melting (SLM), such structures reduce stiffness and increase bone ingrowth. Their porosity mimics the trabecular structure of natural bone, raising mechanical compatibility as well as biological fixation.

[2]

[2]

Fig. 2 Typical biomedical uses of Ti-based alloys.

4. Other Biocompatible Metals:

In addition to titanium-based alloys, several other metals are widely used within biomedical implants due to their excellent biocompatibility and functional characteristics.

- Tantalum (Ta) is most famous for its corrosion resistance and osseointegration, which render it especially suited for applications such as spinal cages and hip replacements. Its ability to allow bone in-growth and resist degradation in body environments is conducive to long-term implant stability.

- Zirconium (Zr), like titanium, forms a stable and inert surface oxide. Such a property qualifies it for use in dental implants and bone screws, where biological compatibility and mechanical performance are important.

- Nickel-titanium alloy, or Nitinol (NiTi), is characterized by its superelasticity and shape-memory effect and high corrosion resistance. Such properties qualify it for minimally invasive devices, e.g., self-expanding stents and orthodontic archwires.

Conclusion

Titanium alloys have revolutionized biomedical implants by their better biocompatibility, corrosion resistance, and mechanical strength. The evolution of beta titanium alloys with low modulus and improved biological behavior is a huge leap towards lessening the stress shielding-related failure of implants. Titanium will continue to be a central material in biomedical engineering for bone replacement, cardiovascular implants, or dental restoration.

Reference:

- Akshaya, S., Rowlo, Praveen, Dukle, Amey, & Nathanael, A. (2022). Antibacterial Coatings for Titanium Implants: Recent Trends and Future Perspectives. Antibiotics, 11, 1719. https://doi.org/10.3390/antibiotics11121719

- Beta Titanium Archwires: Composition and Clinical Use. American Journal of Orthodontics.

- Development of Ti-33Nb-4Sn with Ultralow Modulus and High Strength. Scripta Materialia.

- Effect of Surface Roughness and Porosity on Titanium Implant Osseointegration. Acta Biomaterialia.

- Long-Term Osseointegration of Titanium and Titanium Alloys. Biomaterials Science.

- Low Young’s Modulus and High Strength Beta Titanium Alloys for Biomedical Applications. Nature Materials.

- Maqsood, Muhammad Asad, & Sana, Muhammad. (2023). Potential of titanium based alloys in the biomedical sector and their surface modification techniques: A review. Proceedings of the Institution of Mechanical Engineers Part C: Journal of Mechanical Engineering Science, 237, 1–30. https://doi.org/10.1177/09544062231164506

- Mechanical Properties and Cytotoxicity of Ti-Nb-Zr and Ti-Nb-Ta Alloys. Journal of Materials Science: Materials in Medicine.

- Nitinol: Properties and Applications in Biomedical Devices. Materials Science and Engineering: C.

- Plasma-ion Surface Modification for Ca/Si Enhanced Titanium Biocompatibility. Surface & Coatings Technology.

- Porous Titanium Scaffolds for Bone Regeneration. Advanced Engineering Materials.

- Ti-6Al-4V Cytotoxicity and Biocompatibility Concerns. Journal of Biomedical Engineering.

- Titanium Implants with High Biocompatibility. Sigma-Aldrich Technical Article.

- Use of Tantalum and Zirconium in Medical Devices. International Journal of Implant Dentistry.

- Young’s Modulus of Human Cortical Bone and its Matching with Biomaterials. Journal of Biomedical Materials Research.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}