Rare Earth Tungsten Electrode

Rare Earth Tungsten Electrode

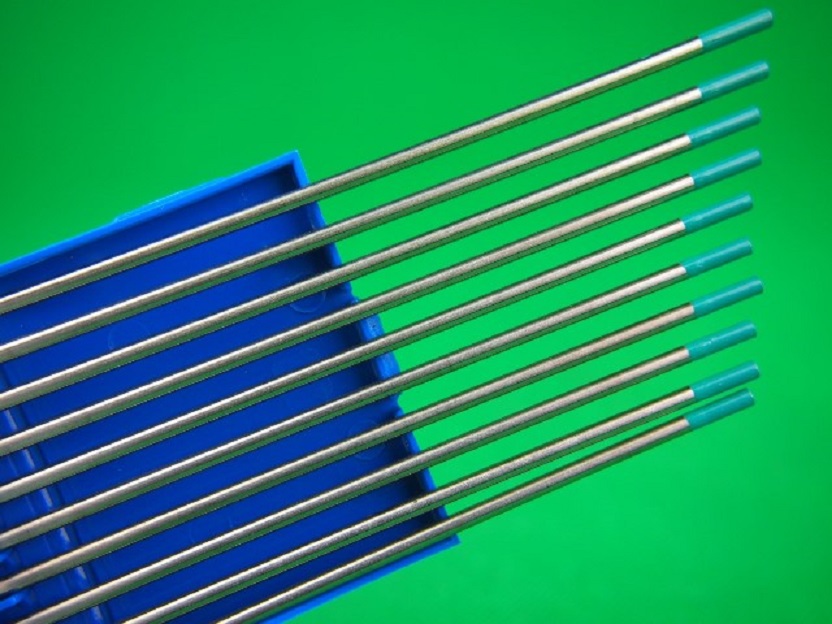

The tungsten electrode is a key material in inert gas-shielded welding and plasma welding, cutting, spraying, smelting, and special electric light sources. At present, thorium tungsten electrodes (including ThO2) and cerium tungsten electrodes (including CeO2) are more commonly used. Thorium tungsten electrodes will bring radioactive hazards to the environment and human health during their production and use. Because of this, researchers have developed a new type of rare earth tungsten electrode with stronger general performance.

Rare Earth Tungsten Electrode

A rare-earth tungsten electrode material without radioactive contamination and with good performance is composed of La2O3 and Y2O3, La2O3 and CeO2, Y2O3 and CeO2, and the rest is W. The content of each rare earth oxide is 0.45 ~ 1.75% (weight), and the total content of rare earth oxides is 2 ~ 2.2% (weight).

The specific preparation method is as follows:

First of all, the rare-earth nitrate is formulated into a solution, mixed into the tungsten trioxide powder, dried, and then reduced by hydrogen at 500-540°C and 640-920°C twice to obtain tungsten powder.

Then, the tungsten powder is pressed, pre-sintered at 1200±50℃, melted, and sintered at 90% fusing current, and then processed into electrodes of various specifications through rotary forging and chain drawing.

The reason why two rare earth oxides are added here is to make the prepared rare earth tungsten electrode material have more advantages than cerium tungsten electrode, lanthanum tungsten electrode (including La2O3), yttrium tungsten electrode (including Y2O3), and thorium tungsten electrode Use performance, but also has good processing performance.

The lanthanum tungsten electrode has good arc stability and electrode anti-burning performance when working at medium and small currents, but its processing performance is poor, and it burns seriously when used at large currents.

The yttrium tungsten electrode has a large arc pressure when used, and the electrode has good anti-burning performance when working with a large current, but its processing is difficult, and the arc stability is poor when used with a small current.

Conclusion

Thank you for reading our article and we hope it can help you have a better understanding of the new type of rare earth tungsten electrode. If you want to learn more about tungsten or other types of refractory materials, we would like to advise you to visit Advanced Refractory Metals (ARM) for more information.

Headquartered in Lake Forest, California, USA, Advanced Refractory Metals (ARM) is a leading manufacturer & supplier of refractory metals & alloys across the world. It provides customers with high-quality refractory metals & alloys such as tungsten, tungsten alloy, niobium, molybdenum, tantalum, rhenium, titanium, and zirconium at a very competitive price.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}