Molybdenum Disilicide vs. Traditional Heating Elements

Traditional materials like Kanthal (FeCrAl), Nichrome (NiCr), graphite, and silicon carbide (SiC) have long been used in various heating systems. However, Molybdenum Disilicide (MoSi₂) is steadily gaining favor thanks to its superior thermal and mechanical performance. We are going to compare MoSi₂ against more conventional heating materials.

Types of Heating Elements

Heating elements are categorized by the materials they are made from, each suited to specific temperature ranges and atmospheric conditions. The most commonly used types include:

- Kanthal (FeCrAl): A durable alloy for medium- to high-temperature applications in air.

- Nichrome (NiCr): A flexible alloy used for resistive heating with good oxidation resistance.

- Graphite: Suitable for very high temperatures but only in inert or vacuum environments.

- Silicon Carbide (SiC): A robust ceramic heater capable of operating in oxidizing atmospheres up to ~1600°C.

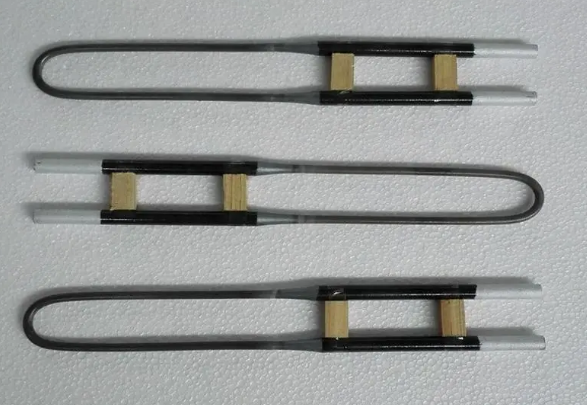

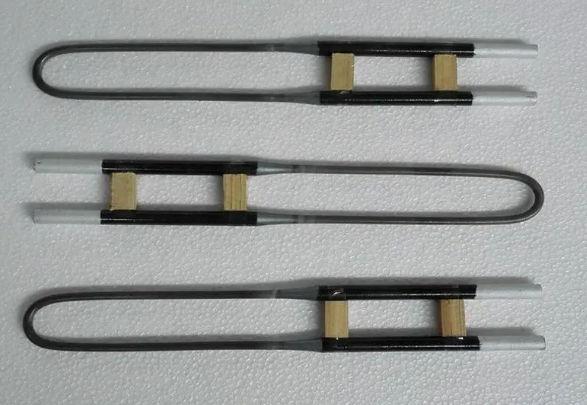

- Molybdenum Disilicide (MoSi₂): A high-performance ceramic-metal hybrid material used in oxidizing atmospheres up to 1800°C.

Each of these materials serves a unique niche, but MoSi₂ and SiC have emerged as leading options for high-performance, high-temperature environments.

Further reading: Heating Elements: Molybdenum Disilicide vs. Silicon Carbide

1. Temperature Capability

|

Material |

Max Operating Temp (°C) |

Atmosphere |

|

MoSi₂ |

1800 |

Oxidizing |

|

SiC |

~1600 |

Oxidizing |

|

Kanthal (FeCrAl) |

~1400 |

Oxidizing |

|

Nichrome (NiCr) |

~1200 |

Oxidizing |

|

Graphite |

~2500 |

Inert/Vacuum |

MoSi₂ leads in high-temperature oxidizing applications, followed by SiC, which also provides strong performance at slightly lower temperatures. Graphite offers exceptional temperature tolerance but requires an inert environment to avoid degradation.

2. Oxidation Resistance

MoSi₂ forms a protective silica (SiO₂) layer, making it exceptionally resistant to oxidation. SiC also develops a similar silicon oxide layer that provides strong protection in oxidizing environments, though it may degrade under severe conditions. Kanthal and Nichrome form oxide scales, but these scales can flake or deteriorate over time with repeated heating and cooling cycles. Graphite oxidizes rapidly in air, making it unsuitable for oxidizing atmospheres.

MoSi₂ offers the highest oxidation resistance at extreme temperatures, and SiC provides a reliable alternative in many oxidizing applications.

3. Thermal Shock and Service Life

MoSi₂ handles rapid heating and cooling without cracking, making it ideal for thermal cycling in high-demand industrial applications. Its unique ceramic-metallic structure allows it to maintain mechanical integrity under repeated temperature fluctuations. SiC, while also a ceramic, is more brittle and susceptible to breakage when subjected to thermal shock. Kanthal and Nichrome tend to warp or embrittle over time due to repeated heating cycles. Graphite, although thermally robust in inert conditions, is fragile in the presence of oxygen.

MoSi₂ stands out for its exceptional thermal shock resistance and longer operational lifespan, particularly in environments that involve frequent temperature changes.

4. Energy Efficiency

MoSi₂ heats quickly and maintains stable output at high temperatures, significantly reducing energy consumption and improving furnace heat-up times. Its ability to deliver consistent, targeted heating improves process control and reduces energy waste. SiC elements also perform efficiently, though they may require longer warm-up times and are slightly less stable at the highest end of their temperature range. Traditional materials like Kanthal and Nichrome are less efficient at elevated temperatures and often experience greater thermal losses.

MoSi₂ enables faster, more efficient heating cycles, while SiC remains a strong performer in moderately high-temperature environments.

5. Application Flexibility

MoSi₂ is widely used in industries that demand clean, high-temperature operation, including:

- High-temperature sintering

- Glass and ceramic processing

- Semiconductor diffusion furnaces

- Powder metallurgy

- Advanced materials research

SiC is commonly used in:

- Kilns for ceramic manufacturing

- Heat treatment applications

- Small-scale laboratory heating systems

Kanthal and Nichrome remain effective in cost-sensitive, lower-temperature applications, while graphite is still preferred in vacuum or inert atmospheres.

6. Cost and Considerations

MoSi₂ heating elements generally have a higher upfront cost compared to traditional materials, but they offer extended service life and reduced maintenance needs, often resulting in lower total cost of ownership over time. These elements require careful handling during installation due to their inherent brittleness. SiC elements are typically more affordable than MoSi₂ and easier to handle, though they may need more frequent replacement in extreme conditions. Kanthal and Nichrome are cost-effective for basic applications but require more regular replacement and maintenance.

Conclusion

Molybdenum Disilicide is a next-generation solution that outperforms traditional heating elements in terms of temperature resistance, oxidation stability, thermal shock durability, and energy efficiency. While Kanthal, Nichrome, graphite, and even silicon carbide continue to serve well in their respective niches, MoSi₂ is the clear choice for high-performance, high-temperature, and high-purity applications. For more molybdenum products, please check Advanced Refractory Metals (ARM).

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}