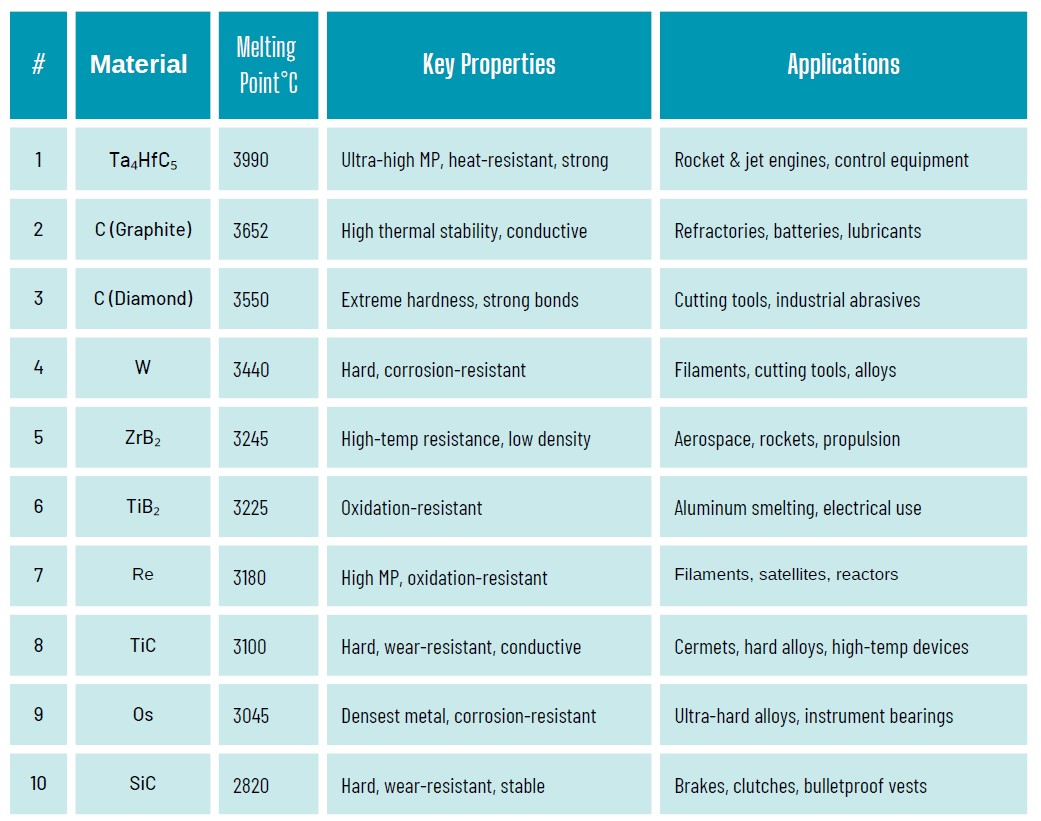

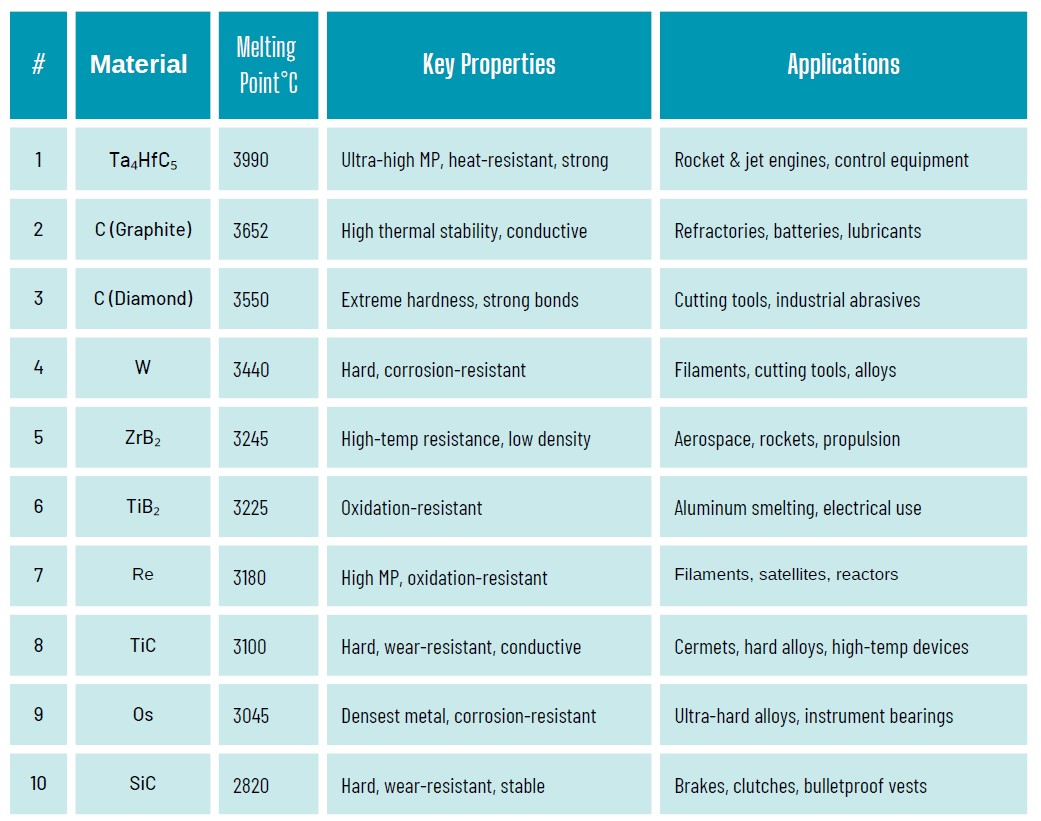

Top 10 Materials with the Highest Melting Point in the World

Want to know what materials have very high melting points? You've come to the right place. In this article, we will introduce the materials with the highest melting point in the world - top 10.

Materials with the Highest Melting Point in the World

1. Tantalum Hafnium Carbide Alloy (3990℃)

Tantalum hafnium carbide alloy takes the 1st place in our list of the materials with the highest melting point.

Tantalum hafnium carbide alloy (Ta4HfC5) actually refers to tantalum and hafnium pentacarbonate compound, which has the highest melting point among known compounds. It can be considered to be composed of two binary compounds, tantalum carbide (melting point 3983 ℃) and hafnium carbide (melting point 3928℃).

Tantalum hafnium carbide alloys are used as heat-resistant and high-strength materials for rocket and jet engines, as well as parts for control and adjustment equipment.

Ta4HfC5

2. Graphite (3652 ℃)

Graphite ranks 2nd in our list of materials with the highest melting point in the world.

Graphite is an allotrope of carbon, where three other carbon atoms (arranged in a honeycomb of hexagons) are covalently linked to each other to form covalent molecules. Due to its special structure, it has high-temperature resistance, electrical and thermal conductivity, lubricity, chemical stability, plasticity, and so on.

Traditional graphite can be used as a refractory material, conductive material, wear-resistant, and lubricating material casting, sand, die and high-temperature metallurgy material, while new graphite is used as flexible graphite sealing material, car battery, new composite material, etc.

Graphite

3. Diamond (3550 ℃)

Diamond is another material that has very high melting points. Diamond is an atomic crystal, while graphite is a mixed crystal. The melting point of graphite crystal is higher than that of diamond, which seems incredible.

However, the bond length of covalent bonds in the flake layer of graphite crystal is 1.42×10-10m, and the bond length of covalent bonds in the diamond crystal is 1.55×10-10m. In covalent bonds, the smaller the bond, the bigger the bond energy, the stronger the bond, the harder it is to break, the more energy you have to provide, so the melting point should be higher.

Diamond is used for cutting tools in arts and crafts and industry, such as drawing die, turning tools, thread cutters, durometer heads, geological and petroleum drill bits, grinding wheel cutters, glass cutters, diamond pens, dresser knives, and abrasive material.

Diamond

4. Tungsten (3400 ℃)

Tungsten takes the 4th spot in our list of the materials with the highest melting point.

Tungsten is a steel-gray or silver-white metal with high hardness, high melting point, and resistance to air erosion at room temperature. As a refractory metal (generally, the melting point is higher than 1650℃) with the highest melting point, it has good high-temperature strength.

Tungsten is mainly used in manufacturing filament and high-speed cutting alloy steel, super hard die, and also used in optical instruments, and chemical instruments.

Tungsten

5. Titanium Boride (3225℃)

Titanium boride snaps up the 5th place in our list of the materials with the highest melting point in the world.

Titanium boride (TiB2) has a gray or grayish-black appearance and a hexagonal (AlB2) crystal structure. As a ceramic, it has excellent thermal conductivity, oxidation stability, and mechanical erosion resistance. Titanium boride is a reasonable electrical conductor and can be used as cathode material in aluminum smelting.

TiB2

6. Zirconium boride (3245℃)

Zirconium boride is also one of the materials with the highest melting point.

Zirconium boride (ZrB2) is a high covalent refractory ceramic material with a hexagonal crystal structure. Its ultra-high temperature ceramics (UHTC) have a melting point of 3246oC, high melting point, relatively low density (about 6.09g/cm 3), and good high-temperature strength.

Zirconium boride can be used for high-temperature aviation applications such as supersonic flight or rocket propulsion systems.

ZrB2

7. Rhenium (3180℃)

Rhenium is another material having a very high melting point that deserves a place on our list.

Rhenium is a metal element and one of the metals with a high melting point. Rhenium, like platinum in appearance, is soluble in dilute nitric acid or hydrogen peroxide but insoluble in hydrochloric acid and hydrofluoric acid.

It can be oxidized to very stable rhenium sesquioxide Re2O7, which is a special property of rhenium. Rhenium can be used to make electrical filaments, satellite and rocket shells, and protective plates for atomic reactors.

Rhenium

8. Titanium Carbide (3100℃)

When it comes to materials with the highest melting point, Titanium Carbide is a solid option.

Titanium carbide (TiC) is a very hard (Mohs hardness up to 9-9.5) refractory ceramic material, which is similar to tungsten carbide. It is an iron-gray crystal with metallic luster and belongs to the sodium chloride type face-centered cubic crystal structure.

Titanium carbide has a high melting point, boiling point, and hardness, as well as good thermal and electrical conductivity, and even shows superconductivity at very low temperatures.

Titanium carbide is widely used in the manufacture of cermet, heat-resistant alloy, hard alloy, wear-resistant material, high-temperature radiation material, and other high-temperature vacuum devices.

Titanium-Carbide-Powder

9. Osmium (3045℃)

Osmium takes ninth place in our list of materials with the highest melting point in the world.

Osmium is the sixth-period Ⅷ group element in the periodic table. It is one of the platinum group metals, a heavy platinum group metal, and is the densest metal known. Osmium is very stable in air, while osmium in powder form is easily oxidized.

Osmium can be used to make ultra-high hardness alloy, osmium with rhodium, ruthenium, iridium, or platinum alloy, commonly used as a record player, tap pen and clock, and instrument bearings.

Osmium

10. Silicon Carbide (2820℃)

Silicon Carbide is another material that has a very high melting point. Our list is not complete if it misses out on Silicon Carbide.

Silicon carbide (SiC) is made of quartz sand, petroleum coke (or coal coke), wood chips (green silicon carbide production needs to add salt), and other raw materials through the resistance furnace high-temperature smelting.

Silicon carbide particles can be sintered together to form very hard ceramics, which are widely used in applications requiring high durabilities, such as ceramic plates in car brakes, car clutches, and bulletproof vests.

SiC

Conclusion

Thank you for reading our list of materials with the highest melting point in the world and hope you enjoyed it. If you know any materials that have very high melting points that deserve a place in our list, feel free to leave a comment below to let us know and we'll add them to this list very soon.

If you want to know more about the materials we've mentioned above and the melting point of metals, you can visit Advanced Refractory Metals (ARM) for more information. Headquartered in Lake Forest, California, ARM is a top manufacturer & supplier of refractory metals and provides customers with high-quality refractory metal products at a very competitive price.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}