How Titanium Is Used Today?

How Titanium Is Used Today?

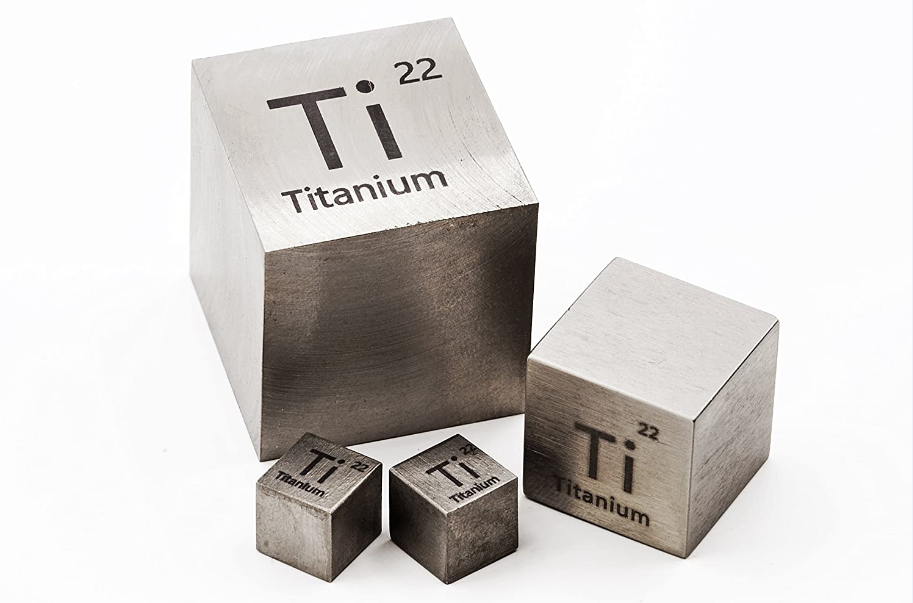

In today's article, we'll take a look at how titanium is used today. Titanium is a hard, shiny, and strong metal. It is as strong as steel but much less dense. It is therefore important as an alloying agent with many metals including molybdenum, aluminum, and iron. Titanium metal connects well with bone, so it has found surgical applications such as in joint replacements and tooth implants.

How Titanium Is Used Today?

Titanium alloys were developed in the early 1950s for defense and aeronautical applications because of their high strength-to-weight ratio. Titanium alloys are mainly used in golf clubs, bicycles, laptops, and crutches. They are also widely used in spacecraft, aircraft, and missiles because of their ability to withstand extremes of temperature and low density.

Titanium Research

Titanium alloys have such varied applications as off-shore drilling equipment, satellites, plating racks, high current superconductors, cryogenic storage vessels, saline water conversion units, wet chlorine gas piping, seawater pumps, eyeglass frames, pulp and paper production, airplanes, yachts, jewelry, golf clubs, dental implants, and hip and knee replacements.

On the other hand, titanium pipes are widely used. For example, titanium pipes are used in power plant condensers because of their corrosion resistance. Titanium is used in desalination plants and to protect the hulls of submarines, ships, and other structures exposed to seawater because has excellent resistance to corrosion in seawater.

The largest use of titanium is in the form of titanium(IV) oxide. It is extensively used as a pigment in enamels, house paint, artists’ paint, plastics, and paper. It is a bright white pigment with excellent covering power. It is also a good reflector of infrared radiation and so is used in solar observatories where heat causes poor visibility.

Titanium in aircraft

Titanium oxide is widely used in sunscreens because it prevents UV light from reaching the skin. Nanoparticles of titanium oxide appear invisible when applied to the skin.

Through innovation in very diverse markets, the production of titanium significantly increased making the material much more readily available. This increase in production has lowered costs allowing even more industries to utilize its unique combination of strength, weight, and corrosion resistance.

Conclusion

Thank you for reading our article and we hope it can be helpful to you. If you want to know more about titanium and other refractory metals, you can visit Advanced Refractory Metals for more information. We provide our customers with high-quality titanium products and other high-quality refractory metals at a very competitive price.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}