How Much Do You Know About Tantalum Niobium?

How Much Do You Know About Tantalum Niobium?

The atomic sequences of tantalum (Ta) and niobium (Nb) are 73 and 41 respectively, both located in the area of the excessive element of VB. They are often symbiotic and are important refractory metals. They have many excellent properties, such as high melting point, high boiling point, low vapor pressure, good cold processing performance, high chemical stability, strong resistance to liquid metal and acid and alkali corrosion, etc.

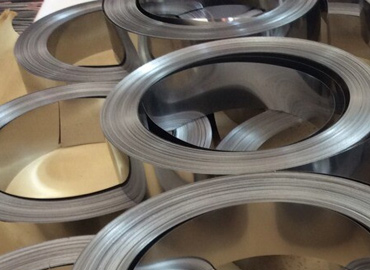

Tantalum Niobium

Tantalum niobium metal and its compounds and alloys are important functional materials, which are widely used in electronics, steel, metallurgy, chemical industry, carbide, atomic energy, aerospace, and other industrial sectors as well as strategic weapons, superconducting technology, scientific research, medical equipment, and other technical fields.

Tantalum and niobium are similar in nature and can be replaced in many fields, but their respective characteristics make tantalum mainly used in electronics, metallurgy, the chemical industry, hard alloys, and other industries.

The electrolytic capacitor of tantalum metal in the electronic industry is characterized by its large capacitance, small leakage current, good stability, high reliability, good pressure resistance, long life, and small volume.

In the metallurgical industry, tantalum niobium is used as an additive to produce high-strength alloy steel, improve various alloy properties, and make super-hard tools. Niobium is mainly used for industrial superconducting technology such as steel, ceramics, and nuclear energy.

About 65% of tantalum is used in the electronics industry, and about 87% of niobium is used in the steel industry in the present world. With the advancement of science and technology, the application field of tantalum-niobium and its alloy and processing materials will be expanded continuously.

Tantalum can store and release energy, which is indispensable in the electronics industry, so tantalum capacitors consume more than half of the world's tantalum production. The tantalum base element can be made very small without reducing the performance of the electronic equipment.

Tantalum is almost ubiquitous as component applications, such as cell phones, hard drives, and hearing AIDS. The biocompatibility of tantalum is very strong, so it is more widely used to make composite materials with cheaper substrates such as stainless steel.

The corrosion resistance of tantalum in the chemical industry is excellent and is used as lining for pipelines, tanks, and tanks. The hardness of tantalum carbide is very high and becomes the ideal material for cutting tools. Tantalum oxide can improve the refractive index of glass lenses.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}