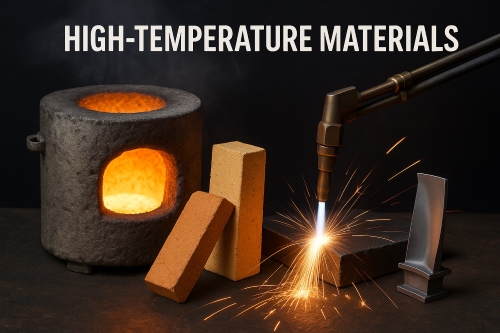

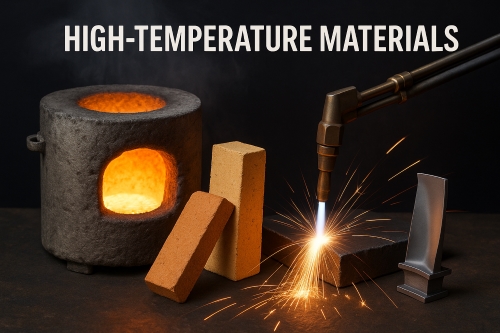

High-Temperature Materials: The Backbone of Extreme Environments

Where the environment becomes very harsh-whether it is inside a jet engine, the thermal shield of a spacecraft, or the high-temperature industrial processes-ordinary materials simply cannot survive. The materials that would thrive under such punishing conditions are known as high-melting-point materials. Such substances sustain structural integrity and performance at thousands of degrees Celsius, making them indispensable in aerospace, industrial manufacturing, and electronic applications, to name a few.

Defining High-Melting-Point Materials

The melting point of any material is the temperature at which the transition from solid to liquid occurs. Most metals and ceramics melt at less than 1500 °C; extremely hard materials have much higher melting points. Some of them, like hafnium carbide, do not melt until well above 4000 °C. It is their resilience to high temperatures, while retaining mechanical strength and chemical stability, that makes them so vital for modern engineering.

High-melting-point materials are normally divided into three kinds:

1. Refractory Metals: These metals have very high melting points, and their examples include tungsten, molybdenum, tantalum, rhenium, and niobium.

2. Advanced Ceramics: Those are compounds such as SiC, B4C, and ZrO2, which, along with hardness, exhibit thermal and chemical stability.

3. Ultra-High-Temperature Ceramics (UHTCs) are those special carbides and nitrides, including but not limited to HfC and TaC, whose melting points reach up to and even surpass 3900 °C.

Each class of material has a unique blend of properties that makes them useful in specific areas, including aerospace, industrial processes, electronic, and advanced manufacturing.

Related reading: All You Need to Know about Refractory Metals

Refractory Metals: Strength under Heat

Among them, tungsten has the highest melting point at 3422 °C among pure metals. With its very high density and thermal conductivity at a value of 19.3 g/cm³, it is also one of the most sought-after materials for jet engine parts, filaments of high-temperature furnaces, and industrial cutting tools. These tungsten alloys, however, can find their place in additive manufacturing and special nozzles for industry where thermal cycling could exceed 2000 °C in repetitive processes.

Rhenium, with its melting at 3186 °C, is used to improve superalloy performance at very high temperatures of turbine components, while the corrosion-resistant nature of tantalum (Ta) at melting 3017 °C has desirable applications in chemical processing equipment. Molybdenum, whose thermal conductivity combines with its machinability at 2623 °C, offers suitable applications in furnace components, equipment for making glass, and molds for high-temperature advanced manufacturing.

The good thermal stability of refractory metals originates from their strong metallic bonds due to the delocalized d-electrons; on the other hand, this property makes refractory metals difficult to process and hence requires high-temperature casting or powder metallurgy techniques.

Ceramics and Carbides: Lightweight and Heat-Resistant

While metals provide toughness, ceramics and carbides have excellent heat resistance and hardness. Silicon carbide SiC resists up to 2730 °C; it is used in high-temperature seals, semiconductors, thermal protection for aerospace vehicles, and as cutting abrasive materials. Boron carbide B4C, melting at 2450 °C, is very hard; thus, it has applications in industrial wear-resistant coatings, abrasives, and high-performance cutting tools.

Ultra-high-temperature ceramics are the most extreme class of materials with melting points at around 3950 °C for hafnium carbide and at around 3880 °C for tantalum carbide, while the application includes hypersonic aerospace components, thermal protection systems, and everything that involves temperatures over 2000-2500 °C. It is often common for engineers to reinforce the UHTCs against brittleness with carbon fibers or other composite structures, providing toughness balanced against the need for heat endurance.

Comparison of Important High-Melting-Point Materials

|

Material |

Type |

Melting Point (°C) |

Typical Applications |

|

Tungsten (W) |

Refractory Metal |

3422 |

Jet engine components, furnace filaments, industrial cutting tools |

|

Rhenium (Re) |

Refractory Metal |

3186 |

High-temperature turbine alloys, superalloys |

|

Tantalum (Ta) |

Refractory Metal |

3017 |

Chemical processing equipment, industrial high-temp components |

|

Molybdenum (Mo) |

Refractory Metal |

2623 |

Furnace parts, molds, glass production |

|

Silicon Carbide (SiC) |

Ceramic |

2730 |

Semiconductors, thermal shields, cutting tools |

|

Boron Carbide (B4C) |

Ceramic |

2450 |

Abrasives, wear-resistant coatings, industrial tools |

|

Hafnium Carbide (HfC) |

UHTC |

3950 |

Hypersonic vehicle components, thermal protection |

|

Tantalum Carbide (TaC) |

UHTC |

3880 |

Industrial cutting tools, aerospace high-temp components |

This comparison shows the range of high-melting-point materials from dense metals such as tungsten, to lightweight ceramics and extremely refractory carbides, each suited to specialized applications in aerospace, industrial, electronic, and manufacturing technologies.

Practical Applications across Industries

1. Aerospace Engineering:

For applications involving very high temperatures in excess of 2000 °C without significant loss of structural strength, tungsten alloys are materials of importance in jet engine turbines, rocket nozzles, and thermal protection systems of space and hypersonic vehicles, as also are SiC composites.

2. Industrial Manufacturing:

Furnace linings, crucibles, molds, and high-temperature cutting tools are made from tungsten carbide, TaC, or SiC, all very hard, resistant to wear, and able to withstand extremely high temperatures. For example, tools made from tungsten carbide can cut through metals that would destroy ordinary steel tools, and such tools are used in high-production environments.

3. Electronics and High-Tech Manufacturing:

Tantalum and molybdenum are widely used in thin-film capacitors, high-temperature electrodes, and power semiconductor devices, where good heat tolerance and electrical conductivity play a major role for reliable operation. Silicon carbide wafers are increasingly common in high-power electronics, enabling devices to operate efficiently at high temperatures.

4. Advanced Materials Research:

Researchers are focusing on the development of refractory composites, UHTC composites, and high-entropy alloys that can combine heat endurance with mechanical toughness. With additive manufacturing techniques, complex geometries and combinations of materials can be realized that were not possible before, opening up perspectives toward more efficient engines, industrial tools, and aerospace structures.

Challenges and Future Directions

Even with extraordinary properties, high-melting-point materials are costly, hard to process, and often subject to oxidation. For example, even tungsten, the most common refractory metal, oxidizes in air above 600 °C, necessitating protective coatings or control of atmospheres during use.

Future work is centered on coating, composite reinforcement, and advanced additive manufacturing to improve oxidation resistance, toughness, and manufacturability. In high-entropy refractory alloys, which combine several refractory elements, excellent thermal and mechanical stability has been achieved; applications span from aerospace propulsion to industrial processes at high temperatures.

Conclusion

High-melting-point materials are the backbone of modern high-temperature technologies, enabling engineers to operate at conditions which would destroy ordinary materials. From tungsten furnace filaments to hafnium carbide thermal shields, these substances make possible extreme precision, performance, and durability in aerospace, electronics, and industrial manufacturing. If you want to know more about the materials we've mentioned above and the melting point of metals, you can visit Advanced Refractory Metals (ARM) for more information.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}