Characteristics & Applications of Titanium Valves

Characteristics & Applications of Titanium Valves

Titanium is an important structural metal. Compared with other metal materials, titanium has two significant characteristics: high specific strength and good corrosion resistance. The main consideration for valve materials is not the mechanical properties of the material, but the corrosion resistance of the material. Therefore, titanium and titanium alloys have become indispensable valve materials, and many kinds of titanium valves can be found on the market today.

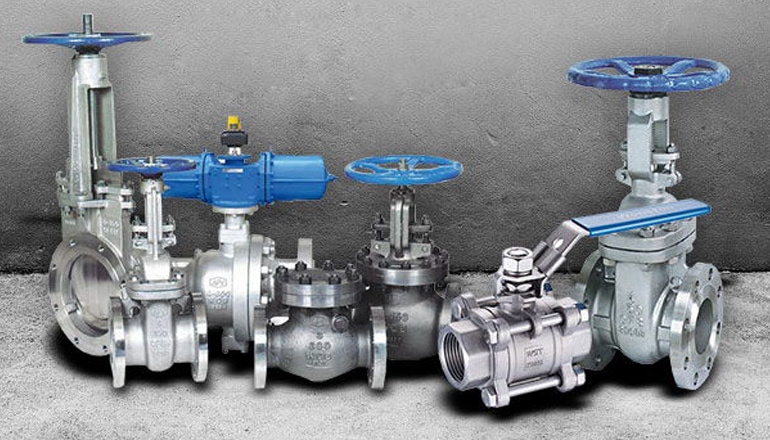

Titanium Valves

Before going any further, let's figure out why titanium metal has excellent corrosion-resistant properties.

The reason why titanium is excellent in corrosion resistance is that titanium is very active in chemical properties and easily reacts with oxygen in the air to form a dense oxide film on the surface. This layer of the oxide film is very stable and difficult to dissolve. It resists the erosion of a variety of corrosive media and can solve the corrosion problem that is difficult to solve for stainless steel, copper, or aluminum valves.

The Characteristics of Titanium Valves

Titanium and titanium alloy valves (hereinafter referred to as titanium valves) mainly have the following characteristics:

1. They not only have good corrosion resistance but also have lightweight and high mechanical strength.

2. They will hardly be corroded in the atmosphere, freshwater, seawater, and high-temperature water vapor.

3. They have good corrosion resistance in aqua regia, chlorine water, hypochlorous acid, wet chlorine, and other media.

4. They are also very resistant to corrosion in alkaline media.

5. They have a very strong anti-chloride ion (CI) ability and excellent anti-chloride ion corrosion resistance.

6. The corrosion resistance of titanium valves in organic acids depends on the acid's reducing or oxidizing properties.

7. The corrosion resistance of titanium valves in reducing acids depends on whether the medium has corrosion inhibitors.

The Applications of Titanium Valves

1. Aerospace Industry

The high specific strength and corrosion resistance of titanium and titanium alloy valves provide a vast space for their application in the aerospace field. Titanium valves are widely used in various pipelines on airplanes, including regulating valves, stop valves, check valves, needle valves, plug valves, ball valves, butterfly valves, etc.

Pure titanium and titanium alloy Ti-6Al-4V are the most common titanium materials used in valves.

2. Chemical Industry

In salt production, synthetic ammonia, nitric acid, acetic acid, and other projects involving strong corrosive media and environments, the corrosion resistance of ordinary metals is difficult to meet the requirements of use, and titanium alloys with better corrosion resistance must be used and controlled. And the adjustment parts in the conveying pipeline must use a large number of titanium valves.

3. Shipbuilding Industry

The Soviet Union was the first country in the world to develop titanium alloys for ships, and it conducted in-depth research on titanium alloys for ships.

In the 1960s and 1980s, the Soviet Union produced a series of attack submarines, including the "Alpha" class submarine with a titanium alloy usage of 3,000 tons and the "Typhoon" class submarine with a titanium usage of 9,000 tons. A large number of titanium alloy pipelines and titanium alloy valves are used in the seawater system of these submarines.

4. Nuclear Power Industry

As nuclear power plants are built along the coast, titanium valves are used in nuclear power projects due to their excellent seawater corrosion resistance. The types include safety valves, pressure-reducing valves, stop valves, diaphragm valves, ball valves, etc.

In addition, titanium valves, as a necessity for fluid control in special media and environments, are also widely used in the paper industry, food and pharmaceutical manufacturing, and other fields, and the future market is very broad.

Conclusion

Thank you for reading our articles and we hope you've enjoyed it. If you want to know more about titanium metal, we would like to recommend you to visit Advanced Refractory Metals (ARM) for more information.

Headquartered in Lake Forest, California, USA, Advanced Refractory Metals (ARM) is a leading manufacturer & supplier of refractory metals across the world. It provides customers with high-quality refractory metals, such as titanium, tungsten, molybdenum, tantalum, rhenium, and zirconium at a very competitive price.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}