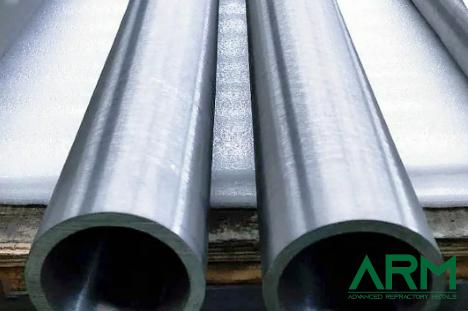

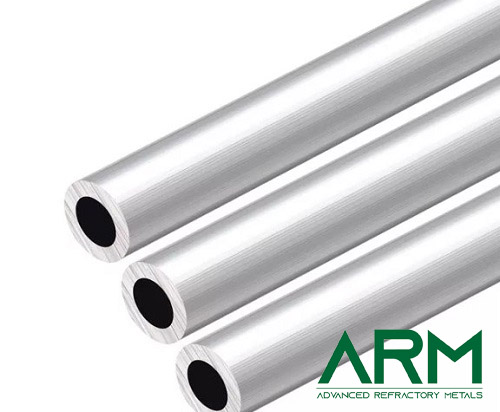

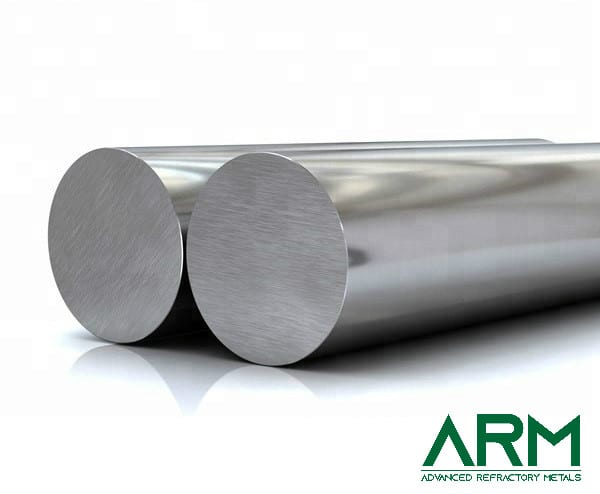

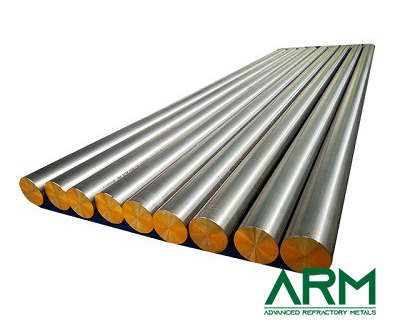

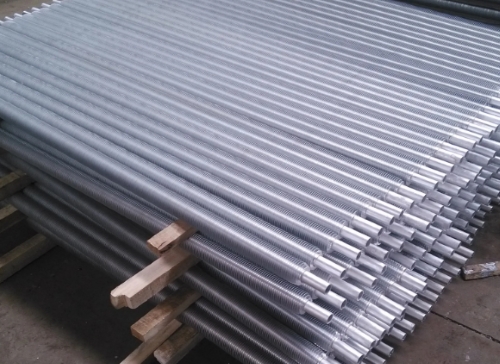

ZR0901 Zirconium Tube/Pipe

In addition to its strong corrosion resistance properties, zirconium pipe and tubing provides erosion protection against fine particles, a feature that’s necessary for the grain processing industry. The materials provide lasting strength in extreme temperatures and chemical environments, including nitric and acetic acid.

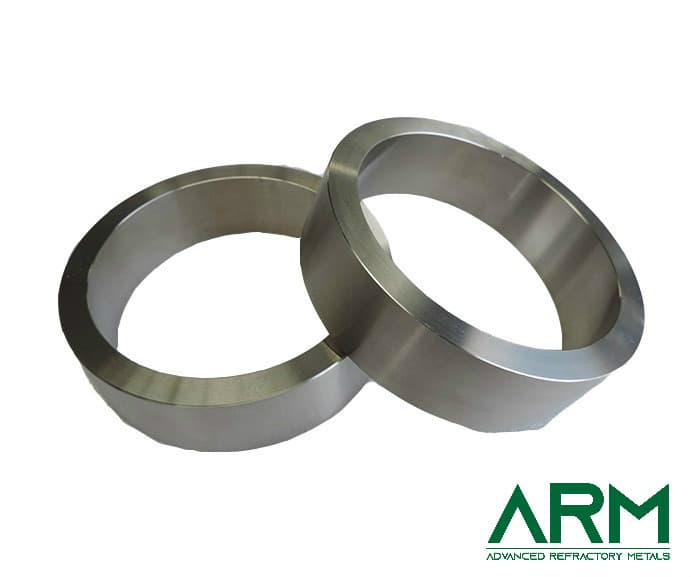

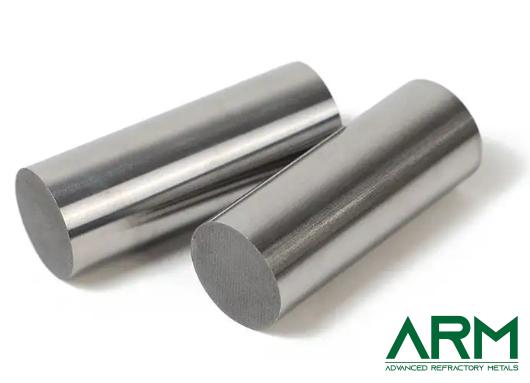

Descriptions of Zirconium Tube / Pipe

Zirconium Pipe is a high-performance metal pipe known for its exceptional corrosion resistance, high strength, and thermal stability. It is widely used in industries requiring extreme durability, such as chemical processing, nuclear energy, and aerospace. Its resistance to harsh environments makes it a preferred choice over traditional metals.

Specifications of Zirconium Tube / Pipe

| Material | R60702 R60704 R60705 and other Zr alloy |

|---|---|

| Standard | ASTM B551 |

| Purity | 95%~99.5% |

| Color | Silver |

| Density | 6.1~6.5 g/cm3 |

| M.O.Q | 100lb (About 120ft of 1"OD tube) |

Chemical composition for Zirconium tube / pipe

| Grade | Zr+Hf | Hf | Fe+Cr | Sn | H | N | C | O | Nb |

| R60702 | 99.2% | <4.5% | <0.20% | - | <0.005% | <0.015% | <0.030% | <0.15% | - |

| R60704 | 97.5% | <4.5% | 0.2-0.4% | 1.0-2.0% | <0.005% | <0.015% | <0.030% | <0.16% | - |

| R60705 | 95.5% | <4.5% | <0.2% | - | <0.005% | <0.015% | <0.050% | <0.16% | 2.0-3.0% |

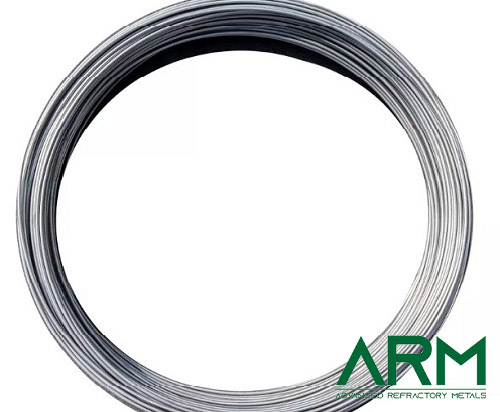

Properties of Zirconium Tube / Pipe

- High Corrosion Resistance: Excellent resistance to acids, alkalis, and seawater.

- Superior Strength: High mechanical strength and durability under extreme conditions.

- Heat Resistance: Withstands high temperatures without significant degradation.

- Biocompatibility: Suitable for medical and pharmaceutical applications.

- Low Thermal Expansion: Maintains dimensional stability under temperature fluctuations.

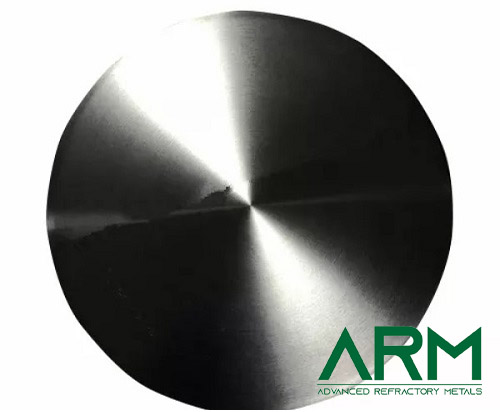

Applications of Zirconium Tube / Pipe

- Chemical Processing: Zirconium Pipe is used in heat exchangers, reactors, and piping systems for handling highly corrosive chemicals.

- Nuclear Industry: Zirconium Pipe is essential for fuel rod cladding and coolant piping due to its low neutron absorption and high-temperature resistance.

- Aerospace: Zirconium Pipe is utilized in high-performance aerospace components exposed to extreme temperatures and corrosive environments.

- Medical Industry: Zirconium Pipe is used in surgical instruments and medical implants due to its excellent biocompatibility.

- Marine Engineering: Zirconium Pipe is applied in seawater handling systems, ship components, and offshore structures due to its exceptional corrosion resistance.

- Power Generation: Zirconium Pipe is integrated into steam condensers and cooling systems for enhanced durability and performance.

- Petrochemical Industry: Zirconium Pipe is ideal for processing and transporting aggressive hydrocarbons and acidic compounds.

- Pharmaceutical Industry: Zirconium Pipe is used in high-purity processing systems to prevent contamination and ensure material integrity.

Packaging of Zirconium Tube / Pipe

Our zirconium tubes and zirconium pipes are clearly tagged and labeled externally to ensure efficient identification and quality control. Great care is taken to avoid any damage which might be caused during storage or transportation.

- Your Name (required)

- Your Email (required)

- Company Name (required)

-

Country (required)

United States

- United States

- Afghanistan

- Aland Islands

- Albania

- Algeria

- American Samoa

- Andorra

- Angola

- Anguilla

- Antarctica

- Antigua and Barbuda

- Argentina

- Armenia

- Aruba

- Australia

- Austria

- Azerbaijan

- Bahamas

- Bahrain

- Bangladesh

- Barbados

- Belarus

- Belgium

- Belize

- Benin

- Bermuda

- Bhutan

- Bolivia

- Bosnia and Herzegovina

- Botswana

- Bouvet Island

- Brazil

- British Indian Ocean Territory

- British Virgin Islands

- Brunei

- Bulgaria

- Burkina Faso

- Burundi

- Cambodia

- Cameroon

- Canada

- Cape Verde

- Cayman Islands

- Central African Republic

- Chad

- Chile

- China

- Christmas Island

- Cocos (Keeling) Islands

- Colombia

- Comoros

- Congo

- Cook Islands

- Costa Rica

- Croatia

- Cuba

- Cyprus

- Czech Republic

- Democratic Republic of Congo

- Denmark

- Disputed Territory

- Djibouti

- Dominica

- Dominican Republic

- East Timor

- Ecuador

- Egypt

- El Salvador

- Equatorial Guinea

- Eritrea

- Estonia

- Ethiopia

- Falkland Islands

- Faroe Islands

- Federated States of Micronesia

- Fiji

- Finland

- France

- French Guyana

- French Polynesia

- French Southern Territories

- Gabon

- Gambia

- Georgia

- Germany

- Ghana

- Gibraltar

- Greece

- Greenland

- Grenada

- Guadeloupe

- Guam

- Guatemala

- Guinea

- Guinea-Bissau

- Guyana

- Haiti

- Heard Island and Mcdonald Islands

- Honduras

- Hong Kong

- Hungary

- Iceland

- India

- Indonesia

- Iran

- Iraq

- Iraq-Saudi Arabia Neutral Zone

- Ireland

- Israel

- Italy

- Ivory Coast

- Jamaica

- Japan

- Jordan

- Kazakhstan

- Kenya

- Kiribati

- Kuwait

- Kyrgyzstan

- Laos

- Latvia

- Lebanon

- Lesotho

- Liberia

- Libya

- Liechtenstein

- Lithuania

- Luxembourg

- Macau

- Macedonia

- Madagascar

- Malawi

- Malaysia

- Maldives

- Mali

- Malta

- Marshall Islands

- Martinique

- Mauritania

- Mauritius

- Mayotte

- Mexico

- Moldova

- Monaco

- Mongolia

- Montenegro

- Montserrat

- Morocco

- Mozambique

- Myanmar

- Namibia

- Nauru

- Nepal

- Netherlands Antilles

- Netherlands

- New Caledonia

- New Zealand

- Nicaragua

- Niger

- Nigeria

- Niue

- Norfolk Island

- North Korea

- Northern Mariana Islands

- Norway

- Oman

- Pakistan

- Palau

- Palestinian Territories

- Panama

- Papua New Guinea

- Paraguay

- Peru

- Philippines

- Pitcairn Islands

- Poland

- Portugal

- Puerto Rico

- Qatar

- Reunion

- Romania

- Russia

- Rwanda

- Saint Helena and Dependencies

- Saint Kitts and Nevis

- Saint Lucia

- Saint Pierre and Miquelon

- Saint Vincent and the Grenadines

- Samoa

- San Marino

- Sao Tome and Principe

- Saudi Arabia

- Senegal

- Serbia

- Seychelles

- Sierra Leone

- Singapore

- Slovakia

- Slovenia

- Solomon Islands

- Somalia

- South Africa

- South Georgia and South Sandwich Islands

- South Korea

- Spain

- Spratly Islands

- Sri Lanka

- Sudan

- Suriname

- Svalbard and Jan Mayen

- Swaziland

- Sweden

- Switzerland

- Syria

- Taiwan

- Tajikistan

- Tanzania

- Thailand

- Togo

- Tokelau

- Tonga

- Trinidad and Tobago

- Tunisia

- Turkey

- Turkmenistan

- Turks And Caicos Islands

- Tuvalu

- US Virgin Islands

- Uganda

- Ukraine

- United Arab Emirates

- United Kingdom

- United States

- United States Minor Outlying Islands

- Uruguay

- Uzbekistan

- Vanuatu

- Vatican City

- Venezuela

- Vietnam

- Wallis and Futuna

- Western Sahara

- Yemen

- Zambia

- Zimbabwe

- Your Phone (Optional)

-

Metals (Optional)

Tantalum...

-

I would like to join the mailing list to receive updates from Advanced Refractory Metals.

- Notes (Optional)

-

Attachment (Optional)

No file chosen

-