Why Is Vanadium A Transition Metal?

Why Is Vanadium A Transition Metal?

The melting point of vanadium is about 1000 degrees lower than that of columbium, so there is much less interest in vanadium for high-temperature applications than in abundant refractory metals.

Why Is Vanadium A Transition Metal?

Pure vanadium has only recently become available in quantities large enough for thorough studies of its physical and mechanical properties and for alloy development. Pure vanadium is relatively ductile and does not work harden appreciably. Therefore, it can be worked easily at room temperature. Because the metal oxidizes rapidly at elevated temperatures, it must be protected during hot working or hot forging. Hot rolling, for example, may be accomplished with the ingot sheathed in a jacket of stainless steel.

Pure vanadium may be extruded, swaged, drawn, stamped, machined, etc., by the usual methods so long as it is not heated to the point where it oxidizes. Components of vanadium can be welded if argon shielding is used or if the welding is done in an enclosed tank containing a protective atmosphere.

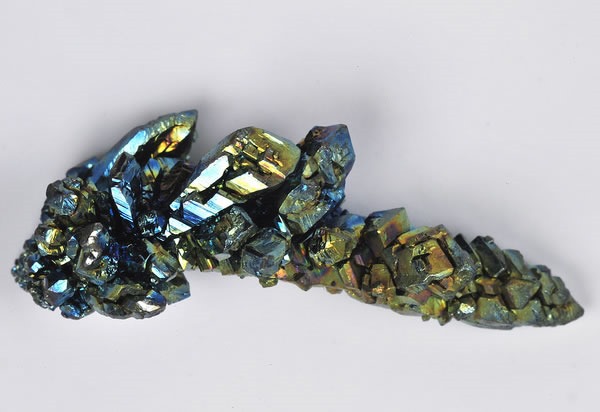

Element vanadium oxidized

Vanadium may have potential use as a structural material for fast reactors because it has a low fission-neutron cross-section, useful strength at elevated temperatures, and high thermal conductivity. Vanadium foil is used as a bonding material in making a titanium-clad steel sheet.

At the present time, vanadium metal is not used extensively in any other application. However, its use as an alloying element in alloy steels, titanium alloys, and in other alloy systems is well known. Alloys of vanadium that appear to be of interest are the vanadium columbium and vanadium-columbium-titanium alloys.

Conclusion

Thank you for reading our article and we hope it can be helpful to you. If you want to know more about vanadium and other refractory metals, you can visit Advanced Refractory Metals for more information. We provide our customers with super high-quality vanadium products and other refractory metals at a very competitive price.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}