4 Uses of Copper Tungsten Alloy You Mightn't Know

4 Uses of Copper Tungsten Alloy You Mightn't Know

Copper tungsten alloy is an alloy composed of tungsten and copper. It combines the advantages of copper and tungsten. For example, this alloy has the advantages of high strength, high specific gravity, high-temperature resistance, arc ablation resistance, good electrical and thermal performance, and good processing performance. Therefore, it has been widely used in the industry and our daily life. In this article, we will introduce 4 uses of copper tungsten alloy that you mightn't know.

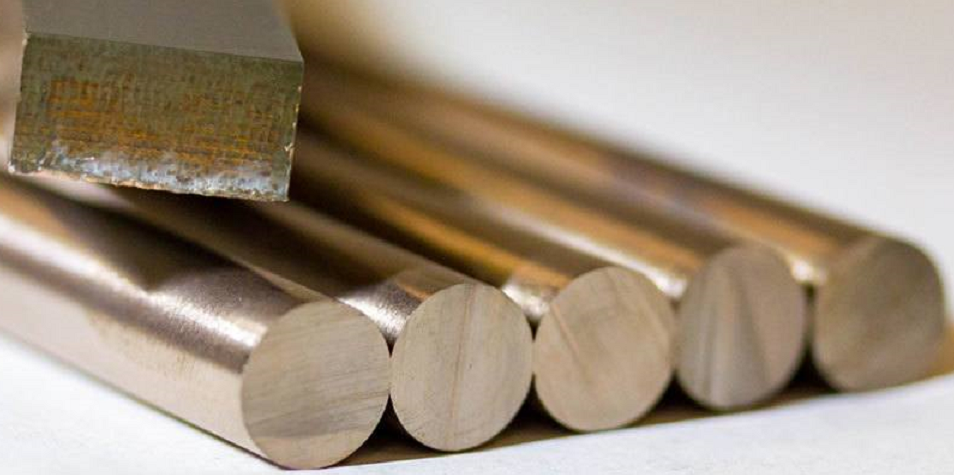

Copper Tungsten Alloy

1. The Uses of Copper Tungsten Alloy in Military High-temperature Resistant Materials

This alloy is used as nozzles, gas rudders, and air rudders for missiles and rocket engines in aerospace because of its high-temperature resistance. At this time, the principle of sweating refrigeration effect formed by the volatilization of copper at high temperatures (copper melting point 1083 ℃) is used to reduce the surface temperature of tungsten copper to ensure its use under extreme high-temperature conditions.

2. The Uses of Copper Tungsten Alloy in High Voltage Switches

This alloy is widely used in high-voltage switches. The main reason is the specific advantages of tungsten-copper alloys such as arc ablation resistance, anti-fusion welding, small cut-off current, and low thermal electron emission capability.

3. The Uses of Copper-Tungsten Alloy in Electro Machining Electrode

The advantages of tungsten copper electrodes are high-temperature resistance, high-temperature strength, arc ablation resistance, good electrical and thermal conductivity, and fast heat dissipation. Its applications are concentrated on EDM electrodes, resistance welding electrodes, and high-pressure discharge tube electrodes.

Electro-processed electrodes are characterized by a wide variety of specifications, small batches, and large totals. The tungsten-copper material used as the electro-machined electrode should have the highest possible density and uniformity of the tissue, especially for those elongated rod-shaped, tubular, and shaped electrodes.

4. The Uses of Tungsten Copper Alloy in Microelectronic Materials

Tungsten-copper electronic packaging and heat sink materials have both low-expansion characteristics of tungsten and high thermal conductivity of copper. Its thermal expansion coefficient and thermal conductivity can be changed by adjusting the composition of tungsten copper, thus providing a wider range of applications for tungsten copper.

Tungsten copper materials have high heat resistance and good thermal conductivity, and at the same time, they have a thermal expansion coefficient that matches silicon wafers, gallium arsenide, and ceramic materials, so they are widely used in semiconductor materials, suitable for high-power device packaging materials, heat sink materials, heat dissipation components, ceramics, and gallium arsenide bases, etc.

Conclusion

Throughout the development history of tungsten-copper alloy materials, with the progress of basic research and the improvement of preparation technology, the performance of tungsten-copper alloy has been greatly improved, and it also provides a broader prospect for the expansion of the application field of tungsten-copper alloy.

Thank you for reading our article, and we hope it can help you have a better understanding of tungsten-copper alloy. If you want to know more about tungsten and other refractory metals, you can visit Advanced Refractory Metals (ARM) for more information. Headquartered in Lake Forest, California, America, ARM is a top manufacturer & supplier of refractory metals across the world, providing customers with high-quality refractory metals such as tungsten, molybdenum, tantalum, rhenium, titanium, and zirconium at a very competitive price.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}