Tungsten Wire Uses in Various Industries

Tungsten Wire Uses in the Lighting Industry:

Tungsten wire is widely used in the manufacture of incandescent light bulb filaments due to its high melting point and ability to emit bright light when heated.

1. Light Bulbs:

Tungsten filaments have been used in incandescent light bulbs since the early 20th century. This application capitalizes on tungsten's high melting point (3422°C or 6192°F) and excellent electrical conductivity. Tungsten's ability to endure high temperatures without melting ensures the filament can glow brightly for extended periods.

Although incandescent bulbs are not very energy-efficient, converting only about 5-10% of electrical energy into visible light, tungsten's durability and the quality of light produced made these bulbs popular for many years.

2. Specialized Lighting Applications:

- Halogen Lamps: These lamps are a type of incandescent lamp but with improved efficiency. They use a tungsten filament enclosed in a small quartz envelope filled with a halogen gas. This design allows the filament to operate at higher temperatures, producing brighter light and improving efficiency and lifespan.

- High-Intensity Discharge (HID) Lamps: Tungsten electrodes are used in HID lamps, which include metal halide lamps, high-pressure sodium lamps, and mercury vapor lamps. These lamps are more efficient than traditional incandescent bulbs and are commonly used in outdoor lighting, stadiums, and industrial settings.

[1]

[1]

- Specialty Lighting: Tungsten filaments are also used in certain photographic lighting, stage lighting, and other applications where precise light quality and high intensity are required.

While the use of incandescent bulbs has significantly declined due to the development of energy-efficient lighting technologies like LEDs and CFLs, tungsten still finds relevance in specialized lighting applications where its unique properties are essential.

Tungsten Wire Uses in Electronics:

It is used in electron emitters in electron tubes and as heating elements in vacuum furnaces. Its high electrical conductivity makes it suitable for electrical contacts and leads.

1. Cathodes and Anodes:

- Vacuum Tubes: Tungsten wire is used in the manufacture of cathodes and anodes for vacuum tubes. These tubes are critical components in older television sets, radios, and various other electronic devices. Tungsten's high melting point ensures that the components can operate efficiently at high temperatures without degrading.

- Electronic Devices: Tungsten cathodes are also used in various electronic devices that require stable and durable components that can withstand high temperatures and provide reliable performance.

2. Heating Elements:

- Industrial Furnaces: Tungsten wire is widely used as a heating element in high-temperature industrial furnaces. Its high melting point and thermal stability make it suitable for processes that require sustained high temperatures, such as metal processing, glass manufacturing, and the production of advanced ceramics.

- Laboratory Equipment: Tungsten heating elements are also used in various laboratory equipment where precise temperature control is necessary. This includes applications in material science research and the production of semiconductor materials.

3. Electrical Contacts and Leads:

- High Electrical Conductivity: Tungsten wire’s high electrical conductivity makes it suitable for use in electrical contacts and leads. This property ensures efficient and reliable electrical connections, making tungsten an excellent choice for components that require both high thermal and electrical performance.

Tungsten Wire Uses in Medical Equipment:

Tungsten wire's durability and biocompatibility make it highly valuable in the medical field, supporting a variety of critical applications:

1. Electrodes in Medical Devices:

- Defibrillators: Tungsten wire is used as electrodes in defibrillators, devices that deliver a therapeutic dose of electrical energy to the heart to restore a normal heartbeat. The reliability and precision of tungsten electrodes are crucial for the effectiveness of these life-saving devices.

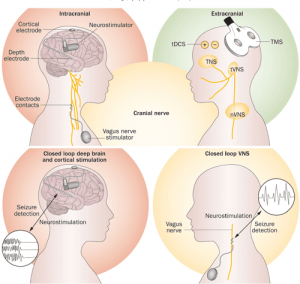

- Neurostimulation Devices: Tungsten electrodes are also used in neurostimulation devices, which are implanted to deliver electrical impulses to specific parts of the nervous system. These devices are used to manage chronic pain, movement disorders, and other neurological conditions. Tungsten’s strength and resistance to corrosion ensure that these electrodes can function reliably over long periods.

[2]

[2]

2. X-ray Tubes:

Filament in the Cathode: Tungsten wire is used in the cathodes of X-ray tubes, where it serves as the filament. When heated, the tungsten filament emits electrons, which are then accelerated and directed towards a target to produce X-rays. Tungsten’s high melting point and thermal stability are essential for generating the high-energy X-rays required for medical imaging. This application is crucial in diagnostic radiology, providing detailed images of the body's internal structures.

Tungsten Wire Uses in Aerospace and Defense:

Tungsten wire is used in high-temperature applications, including aerospace components and defense equipment like missile nozzles and other heat-resistant applications.

1. Aerospace Applications:

- Rocket Nozzles: Tungsten wire is used in the production of rocket nozzles, which must withstand the extreme heat and pressure generated during rocket launches. Tungsten’s high melting point and robustness ensure that these nozzles maintain their structural integrity and performance under such intense conditions.

- Space Missions: Tungsten’s properties are also valuable in various components used in space missions, where materials must perform reliably in the harsh environment of space, including high radiation levels and extreme temperature variations.

2. Defense Applications:

- Armor-Piercing Projectiles: Tungsten wire is utilized in the manufacture of armor-piercing projectiles. The high density of tungsten allows these munitions to penetrate armor more effectively than those made from other materials, providing a significant advantage in military operations.

- High-Performance Ammunition: Tungsten is also used in other types of high-performance ammunition, including kinetic energy penetrators, which rely on the material’s density and strength to deliver maximum impact and penetration.

Tungsten Wire Uses in Manufacturing:

In the welding industry, tungsten wire is used in gas tungsten arc welding (GTAW) or tungsten inert gas (TIG) welding for its high melting point and strength.

1. Tungsten Inert Gas (TIG) Welding:

Electrode: Tungsten wire serves as the electrode in TIG welding. This welding technique requires an electrode that can endure high temperatures and maintain a stable arc. Tungsten wire’s ability to handle these conditions makes it the ideal choice, providing precise and high-quality welds for various industrial applications.

[3]

[3]

2. Precision Cutting Tools:

Wire Cutters and Saws: Tungsten wire is used in precision cutting tools such as wire cutters and saws. These tools are employed in cutting hard materials like metal and ceramics. Tungsten’s hardness and durability ensure that the cutting tools can perform efficiently and accurately, even with tough materials.

Tungsten Wire Uses in Scientific Research:

It is utilized in various types of scientific equipment, including mass spectrometers and as probe tips in scanning tunneling microscopes due to its stability and precision.

1. Electron Microscopes:

Thermal Conductivity: Tungsten wire is used in the electron emission sources of electron microscopes. Its high thermal conductivity allows it to maintain stability under the intense heat required to emit electrons for imaging. This is crucial for achieving high-resolution images in scientific research and industrial applications.

2. Mass Spectrometers:

High-Temperature Environments: In mass spectrometers, tungsten wire is used in ion sources where high temperatures are required to ionize samples. Tungsten's ability to withstand these temperatures without melting or deteriorating ensures the reliability and accuracy of mass spectrometry analyses.

Conclusion

From lighting and electronics to medical equipment, aerospace, defense, manufacturing, and scientific research, tungsten wire uses are essential in advancing technology and enhancing the performance and reliability of various applications. For more details, please visit Advanced Refractory Metals (ARM).

Related reading:

The Most Refractory Metal Tungsten

What Are The Main Uses Of Tungsten Wire?

Reference:

[1] Silva, Deborah & Boccaccini, Aldo. (2008). Industrial Development in the Field of Optically Transparent Inorganic Materials: A Survey of Recent Patents. Recent Patents on Materials Science. 1. 56-73. 10.2174/1874465610801010056.

[2] Trinka, E., & Brigo, F. (2019). Neurostimulation in the treatment of refractory and super-refractory status epilepticus. Epilepsy & Behavior, 101.

[3] Błachnio, Józef & Kułaszka, Artur & Chalimoniuk, Marek & Woźny, Piotr. (2016). Exemplification of Tomographic Method to Evaluate the Quality of Welded Joints Made from EN 5754-H22 Alloy. Research Works of Air Force Institute of Technology. 39. 10.1515/afit-2016-0018.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}