Tungsten Metal Has Facilitated The Development Of The Aerospace Industry

Tungsten Metal Has Facilitated The Development Of The Aerospace Industry

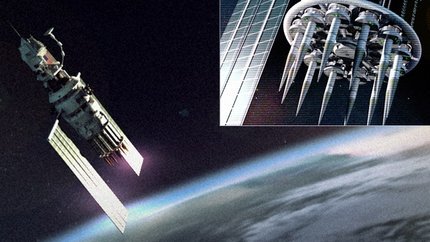

Space, once the arena of great power rivalry, now depends on international cooperation for its costly endeavor. The aerospace industry represents the economic, military, and technological level of a country, and is also an important symbol of a country's comprehensive national strength and national defense strength. Of course, the development of the aerospace industry requires the help of tungsten metal.

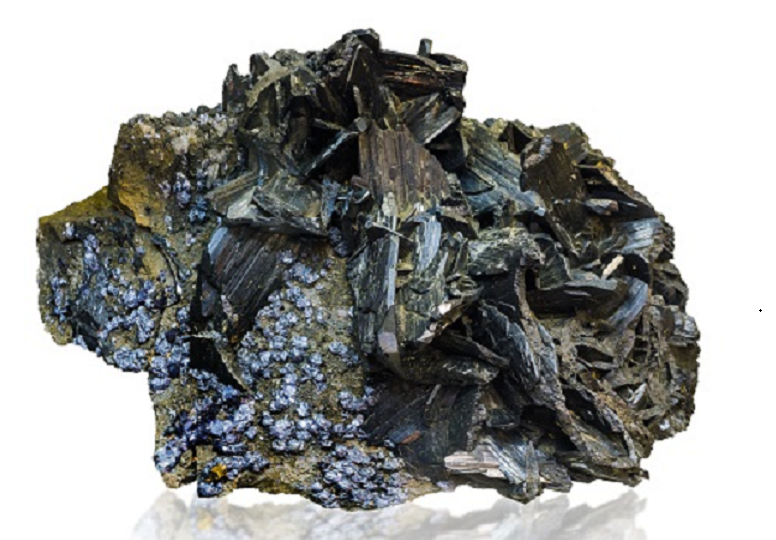

Tungsten Metal

Tungsten is the most heat-resisting metal. Tungsten metal has high density, high strength, high modulus of elasticity, low coefficient of expansion, and low vapor pressure, while tungsten alloy with alloying elements has good abrasion resistance, corrosion resistance, electrical conductivity, and thermal conductivity.

The mechanism design and safety performance of aerospace equipment are closely related to the physical, chemical, and mechanical properties of the materials used, and tungsten metal has a series of excellent physical and chemical properties that can meet the requirements of material properties for aerospace and has been widely used in satellite, aircraft, aircraft engines, and other equipment some key components.

Tungsten Balance Weights

Tungsten alloy is the rotor material of the gyroscope. It is well known that gyroscopes are the heart of navigation and control systems such as satellites, rockets, missiles, aircraft, submarines, and torpedoes. The stability of the gyroscope increases with the weight of the gyro, and the stability and control accuracy of the gyroscope can be greatly improved by using tungsten alloy as the rotor.

Tungsten and its alloys can be used to make uncooled rocket nozzles, ionic rings for ionic rocket engines, jet blades and positioning rings, thermal gas reflectors, and gas rudders.

If tungsten instead of molybdenum is used for the import of solid rocket motor casing and throat lining, the use temperature of the material can be increased from 1760 ℃ to 1760 ℃ or more. For example, the nozzles of the American Polaris A-3 missile are made of a high-temperature tungsten pipe with 10 ~ 15% silver penetration and the Apollo rockets were also made of tungsten.

Tungsten copper composite (W-Cu composite) material can be used as a rocket engine nozzle baffle plate. It is enough to handle more than the tungsten combustion temperature of melting point is 3400 ℃.

Besides, the material is also suitable for rocket engines, hypersonic aircraft leading edge, and thermal shielding of re-entry vehicles. The ultra-sonic aircraft developed in the United States is reportedly covered with about 400 kilograms of tungsten except for the head cone.

The United Technologies Center of the United States has produced a boron-coated tungsten wire for aerospace equipment, which has the advantages of high strength, low density, and high stiffness and can be used as the shell of a rocket or the skeleton of a spaceship.

Besides, high-purity tungsten rods are also widely used in rockets, satellites, airplanes, and ships.

Tungsten Rod

Moreover, adding rhenium into the tungsten alloy can improve the properties of tungsten at high temperature and room temperature, and reduce the plastic-brittle transition temperature.

Tungsten-rhenium alloys with good abrasion resistance and weldability are harder than pure tungsten, and its tensile strength at room temperature is up to 3260MPa, which is suitable for use as space station nuclear reactor material. Tungsten and its alloy coatings have high strength and thermal stability and can prevent nozzles from corrosion and erosion.

Conclusion

Thank you for reading our article, hoping it can be helpful to you. If you want to find more information about tungsten metal or other refractory metals, we advise you to visit Advanced Refractory Metals (ARM) for more information.

Headquartered in Lake Forest, California, Advanced Refractory Metals (ARM) is a leading manufacturer and supplier of refractory metals across the world. We provide our customers with high-quality refractory metal products like tungsten, molybdenum, tantalum, rhenium, titanium, zirconium, etc. at a very competitive price.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}