Spherical Tantalum Powder for 3D Printing

Introduction

Tantalum is a rare, hard, and corrosion-resistant metal that has many industrial applications. Recently, spherical tantalum powder has gained popularity in the field of 3D printing. In this article, we will discuss its properties and applications in this field. Hope that you can have a better understanding and get quality spherical tantalum powder for your business or research.

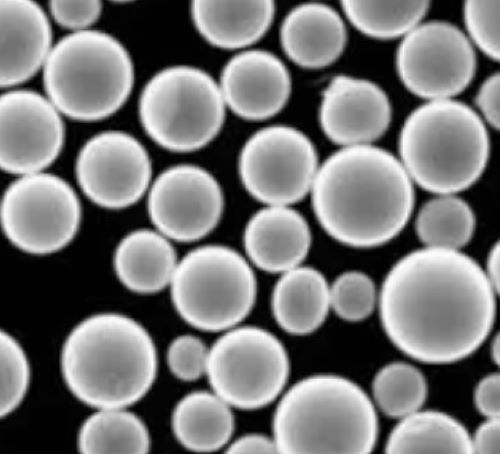

Spherical Tantalum Powder

What Is 3D Printing Powder?

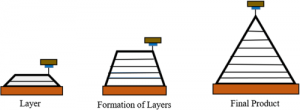

3D printing, or additive manufacturing (AM), is a popular manufacturing approach. This method generates three-dimensional objects layer-by-layer under computer control and possesses wide applications in healthcare, automotive, aerospace, etc.

Layer-by-layer 3D Printing [1]

3D printing powders are of great significance in the whole manufacturing process. You can find the trace of powders in binder jetting, powder bed fusion, sheet lamination, and directed energy deposition, all of which are essential divisions of 3D printing.

To ensure high-quality and repeatable AM powder production at large scales, powders have to meet the following requirements.

- Particle Size Distribution (PSD): Smaller particles are preferred because they can form thinner and more delicate layers compared with those produced by larger particle powders.

- Morphology: Regular-shaped powder particles with smooth surfaces are preferred because they can get well-packed particles and tougher components.

- Flowability: Powder with better flow performance is preferable since flowability plays a key role in the formation of homogenous powder layers.

What Are the Benefits of Spherical Tantalum Powder?

Spherical tantalum powder is produced by atomizing molten tantalum using gas or liquid. This process creates a powder with a spherical shape, which has a uniform particle size distribution.

Spherical tantalum powder shares the following benefits with tantalum metal.

- Impressive Thermal Performance: Tantalum has a high melting point of 2996°C, and it is highly conductive to heat, which makes it ideal for high-temperature applications.

- Remarkable Chemical Stability: Tantalum is highly resistant to corrosion and can withstand harsh chemicals and environments. It can only be dissolved with hydrofluoric acid.

- High Density: Tantalum has a high density of 16.6g/cm3, making it popular for applications that require a high mass-to-volume ratio.

In addition, spherical tantalum powder has several features that render it useful for 3D printing, including excellent flowability and uniform particle size distribution.

Advanced Refractory Metal (ARM) is a leading supplier of high-purity spherical tantalum powder for 3d printing tech because these particles have a uniform particle size, easy dispersion, high surface area, and great handling and flow properties.

Related reading: 3D Printing Powder: What is it & How is it Used?

How Is Spherical Tantalum Powder in 3D Printing Used?

Thanks to these characteristics, spherical tantalum powder finds several applications in the field of 3D printing.

- Medical Implants

Apart from the three most representative features mentioned above, tantalum is also biocompatible and non-toxic, which makes it an ideal material for medical implants. Spherical tantalum powder can be used to create custom implants that are tailored to the patient's specific needs. For instance, these powders can be applied to manufacture orthopedic implants because of tantalum’s non-toxicity, high strength, and resistance to corrosion.

Related reading: Application of 3D Printing Tantalum Powder in Biomedicine

- Aerospace Components

Tantalum has a high melting point and great resistance to corrosion, rendering it useful in aerospace applications to withstand harsh environments and extremely high temperatures. Spherical tantalum powder can be utilized to create components such as rocket nozzles and turbine blades.

- Chemical Processing

Tantalum is highly resistant to corrosion and can withstand harsh chemicals and environments. Spherical tantalum powder can be applied to create components for chemical processing applications.

- Electronics

Tantalum's high density allows it to store a large amount of electrical charge per unit volume, making it an excellent conductor of electricity. Spherical tantalum powder can be employed to make capacitors, transistors, and other electronic components.

Conclusion

Spherical tantalum powder stands out for its high melting point, corrosion resistance, and high density, as well as uniform particle size, high surface area, and great flow properties. It also finds a wide range of applications, including medical implants, aerospace components, chemical processing, and electronics. As the field of 3D printing continues to grow, we can expect to see more applications of spherical tantalum powder in the future.

Advanced Refractory Metal (ARM) has rich experience in the manufacture and sale of spherical tantalum powder. You can get capacitor tantalum, metallurgical tantalum, and voltage tantalum powder. Customization is also welcome. Send us an inquiry if you are interested.

Reference:

[1] Thakur, Vishal & Singh, Roopkaran & Kumar, Ranvijay & Gehlot, Anita. (2022). 4D printing of thermoresponsive materials: a state-of-the-art review and prospective applications. International Journal on Interactive Design and Manufacturing (IJIDeM). 1-20. 10.1007/s12008-022-01018-5.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}