Micro Tantalum Powders for Medical Application

Tantalum powders and its applications

Tantalum powders are dark grey combustible metal powder with a high density and excellent thermal and electrical conductivity properties. And they are widely used in many applications, especially medical applications.

Tantalum Powders

- tantalum capacitors and superalloys

- tantalum mill products

- the new generation of tantalum sputtering target

- alloy additives and high temperature or corrosive resistant coating

- 3-D printing

Medical Tantalum Powder vs Ordinary Tantalum Powder

The purity of medical tantalum powder, in a spherical or nearly spherical shape, is usually more than 99%. And its oxygen content is required less than 1000ppm, in particular.

Medical tantalum powder is used in the preparation of medical porous tantalum implant materials. Its high sintering strength, uniform porous tantalum pore size after producing, stable mechanical properties, high purity, and good biocompatibility make tantalum powder become an ideal material for human bones.

Ordinary metallurgical grade tantalum powder’s oxygen content is usually over 1000ppm, and there is no crucial requirement on particle size. Normally, the particle size is -100mesh, -200mesh and -325mesh. In the field of powder metallurgy, metal powder particles can be spherical, nearly spherical, flake-like, dendritic, porous sponge-like and etc.

Difficulties in the Preparation of Medical Tantalum Powder

Tantalum metal powder used as a raw material for the production of medical porous tantalum implant materials has a great influence on essential properties of sintering mechanics and biocompatibility of porous tantalum implant materials.

For example, the complex shape of the powder will cause larger unit mass than the surface area too much resulting in extremely high oxygen content, which is unfavorable for special purpose products.

At the same time, another problem caused by high oxygen content is the sintering temperature increased, leading to difficult sintering and higher-level requirements for sintering equipment. This is another problem came up with.

Besides, connections inside particles have strong parts and weak parts due to uneven sintering among complex particles. It results in unqualified mechanical properties

Traditional Preparation Method and Advanced Refractory Metals (ARM) Tantalum Powder Preparation

There are two existing processes for preparing tantalum powders.

The first one is using a traditional ball mill or Raymond mill or others to make tantalum particles into powder and classifying powder to meet customer requirements. The rest of unqualified powder, either too large or too small will be degraded and used. Thus, the cost increases by 30% - 40% because the prepared tantalum powder can only be partially used. In addition, there will be another 20% -30% increased cost when considering labor and depreciation of equipment.

The second one is fluidized bed jet mills, which produce more complicated powder and higher oxygen content than average.

The medical tantalum powder prepared by ARM using the new process can be applied in the preparation of medical porous tantalum implant materials. It becomes an ideal material for making human bones because of its high sintering strength, uniform pore size, stable mechanical properties, high purity, and favorable biocompatibility.

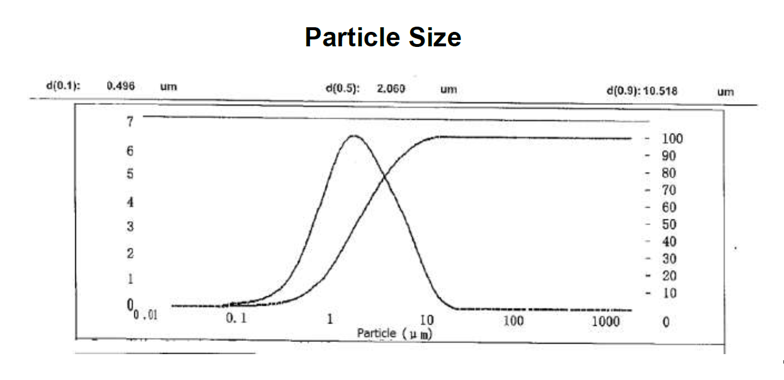

ARM offers D50 2-3um fine particle tantalum powder in stock, with low oxygen content, concentrated particle size distribution, favorable price. Send an inquiry to find more information you need.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}