How Refractory Metals were Discovered and Developed?

How Refractory Metals were Discovered and Developed?

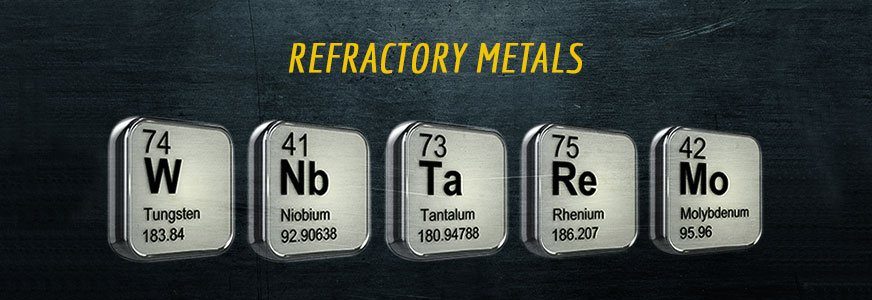

In today's article, we'll take a look at how refractory metals were discovered and developed. Refractory metals are referred to elements or alloys with melting points over 3002℉, such as tungsten, molybdenum, tantalum, niobium, titanium, zirconium, hafnium, vanadium, chromium, rhenium and alloys including tungsten alloys, molybdenum alloys, niobium alloys, titanium alloys, vanadium alloys, chrome alloys, rhenium alloys, chromium and zirconium alloys, tantalum and button alloys, etc.

How Refractory Metals Were Discovered and Developed?

Refractory metals usually can be manufactured into sheet, strip, foil, pipe, bar, thread, profile, and powder metallurgy products.

History

Since refractory metals have very active chemical properties and their extraction processes are complicated, it was late that people discovered refractory metals for the first time.

Molybdenum was first discovered in 1782 by Swedish chemist Jimmer (P.J. Hjelm). Tungsten powder was first extracted by the Spanish de Luer brothers in 1783 with the Carbon reduction method.

Chrome was extracted by French chemist L.N.Vauquelin in 1798. In 1866, C.W. Bromstrand discovered niobium by hydrogen reduction of niobium chloride. Plastic tantalum was first extracted by a German called Bolton in 1903.

Metal zirconium and titanium were first discovered respectively in 1824 and 1910. Metal rhenium had not been discovered until 1925. It is until the 20th century that refractory metals were widely used.

In 1909, W. D. Coolidg, an American, for the first time used powder metallurgy method to produce tungsten billet. After swaging and stretching, the material became tungsten wires for light bulbs.

In 1910, molybdenum was processed into rods, pieces, and wires. In the mid-1940s, the rapid development of refractory metal materials and their processing technology develops quickly due to the needs of aviation, aerospace, electronics, and atomic energy technology.

Therefore, refractory metal melting, powder metallurgy, and plastic processing were promoted. In the 1940s, the first vacuum white electric arc furnace appeared. In the 1950s, an electron beam smelting furnace was invented.

Electron Beam Smelting Furnace

From the 1960s, there were many new technologies, including cold, and hot isostatic pressing, precision casting, isothermal deformation, welding, and a series of powder metallurgy, casting, plastic processing, heat processing, and so on.

With these advanced technologies, a large number of refractory metal and refractory alloy materials were produced. In 1956, A. Cadverly extracted tungsten, molybdenum and rhenium single crystals with purity higher than 4N with electron beam suspension area smelting technology.

China's refractory metal materials research and development started from 1950s. In 1953, Shanghai bulb factory produced China's first φ0.18mm tungsten wire. In 1956, Beijing Electron Tube Factory built the first complete tungsten and molybdenum processing workshop in China.

From 1952 to 1960, a lot of refractory metal research institutions were set up, such as the Ministry of Metallurgical Research Institute of Metallurgical Materials, Institute of Metals, Ministry of Metallurgy, Shanghai Institute of Nonferrous Metals, etc.

They successfully extracted tungsten, molybdenum, tantalum, niobium, titanium, zirconium, hafnium, vanadium, rhenium, and other refractory metals. Besides, they built processing equipment, like vacuum white arc furnaces, vacuum melting furnaces, and electron beam smelting furnaces.

Moreover, they successfully produced a variety of refractory alloy plates, belts, bars, wires, and other products. In 1958, Zhuzhou Cemented Carbide Plant was put into use and gradually developed into an important production base of tungsten, molybdenum, niobium metal, and cemented carbide in China.

From the 1960s to 1970s, more refractory metal smelter and processing factories were set up, such as Zigong Carbide Plant, Baoji nonferrous metal processing plant, and so on.

Equipped with a series of large-scale smelting and processing equipment, these factories developed and produced a large number of new products for use, such as tungsten and tungsten copper rocket nozzle, tungsten rhenium thermocouple, high-density tungsten alloy, tungsten silver and tungsten copper contacts, tungsten and molybdenum foil, large molybdenum alloy sheet, wall tantalum tube, capillary niobium tube, zirconium alloy tube and titanium alloy tube, and tungsten, molybdenum, tantalum, niobium, vanadium, zirconium, and titanium single crystal.

In the 1980s, there were more than 40 research and production unit engaging in refractory metal materials in China, which formed a complete scientific research& production system with the ability to produce more than 100 kinds of refractory metals and alloys.

Refractory metal materials conclude varieties of sheet, strip, strip, foil, pipe, bar, wire, Powder products, and so on. Refractory metals and refractory alloys in the world market can now be basically produced in China.

Tungsten Wire

Conclusion

Thank you for reading our article and we hope you've enjoyed it. If you want to know about how refractory metals were discovered and developed and the applications of refractory metals, you can visit Advanced Refractory Metals for more information. We provide our customers with high-quality refractory metals at a very competitive price.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}