How Is Molybdenum Metal Used in Vacuum Furnace Hot Zone?

Introduction

Molybdenum metal is employed in a variety of industries like electronics, semiconductors, glass-making, and most importantly heating applications. For instance, there is a range of vacuum furnace hot zones made from molybdenum metal.

Figure 1. Molybdenum Sheets

Therefore, this article is going to explore how molybdenum metal is applied to manufacture heating apparatus using a specific case. Hope that you can have a better understanding of the types and benefits of molybdenum metal used in vacuum furnace hot zone.

What Is A Vacuum Furnace?

A vacuum furnace is a type of heating equipment with lots of components used in a vacuum surrounding. Generally, it is composed of vacuum vessels, hot zones, pumping systems, cooling systems, and temperature & vacuum control systems. Among them, the hot zone is the heart of a vacuum furnace because it largely affects the process quality, the temperature, the pressure, and the operating cost.

Figure 2. A Vacuum Furnace

What Are the Benefits of A Vacuum Furnace?

A reliable vacuum furnace comes with the following advantages.

- Less Heat Loss: There is no air in the chamber, so there would be less heat loss caused by air convection. Additionally, the temperature in a vacuum furnace is well controlled within the hot zone.

- Less Contamination: A vacuum furnace features low contamination by carbon, oxygen, and other gases since there is no air inside.

- High Purity: The pumping systems remove low-temperature by-products, so we could get a higher purity end product.

- Controlled Process: The process can be computer-controlled.

With these desired properties, vacuum furnaces are used to carry out heating processes such as annealing, sintering, brazing, hardening, and tempering.

Why Choose Molybdenum for Vacuum Furnace?

Molybdenum is used to manufacture vacuum furnace apparatus for the good points below.

- High Melting Point: Molybdenum has a high melting point of 2,623 °C (4,753 °F). Only tantalum, tungsten, and carbon have higher melting points.

- High Hardness at Elevated Temperature: Molybdenum is a strong grayish metal with a Mohs hardness of 5.5.

- Perfect Thermal Properties: Molybdenum metal has high thermal conductivity, a low coefficient of expansion, and remarkable thermal shock resistance.

- Great Resistance: This refractory metal is highly resistant to corrosion and creeps.

How Is Molybdenum Used in Vacuum Furnace Hot Zone?

You could find molybdenum metal in the major components of a vacuum furnace hot zone: the heating elements where other parts are based; the insulation or heat shields; and the hearth that supports other devices.

1. Molybdenum Metal Used in Heating Elements

Molybdenum is a popular heating element material used in the vacuum furnace hot zone due to its high operating temperature. Apart from it, using molybdenum decreases impurities introduced in the process, while graphite might cause contamination. Molybdenum heating elements are extensively used in the medical, electronics, and aerospace industries which require clean environments for sensitive materials.

Figure 3 Molybdenum Heating Elements

2. Molybdenum Metal to Make Heat Shields

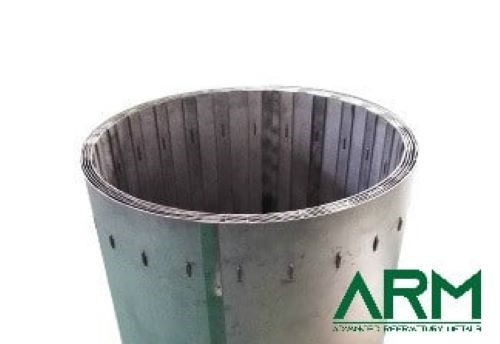

Multiple layers of molybdenum heat shield sheets are commonly used in a vacuum furnace hot zone to prevent heat conduction from the central area of the heat field. Namely, there are many layers of heat-shield sheets in the hot zone. They lay parallel to each other and have a large space between them. For higher operating temperatures, more molybdenum metal layers are needed, and the space in between changes as well.

Figure 4 Molybdenum Heat Shields

Conclusion

Molybdenum metal is used to manufacture heating elements, heat shields, and hearth support in the vacuum furnace hot zone because it has high strength and ideal thermal features. Advanced Refractory Metals (ARM) is a leading supplier of molybdenum products of different sizes and shapes. There are molybdenum sheets, plates, rods, bars, and alloys available. Check our site for the most suitable molybdenum products.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}