Hafnium Composites: Among the Most Heat-Resistant Materials

Introduction

Hafnium composites are recognized as some of the most heat-resistant materials available today. Leveraging the remarkable properties of hafnium, these composites are designed to endure and perform in environments requiring extreme thermal stability and resilience. Their unique characteristics make them indispensable across various high-stakes industries, including aerospace, nuclear energy, and advanced manufacturing.

Key Properties of Hafnium Composites

- High Melting Point: Hafnium itself boasts a melting point of around 2,233°C (4,051°F). When incorporated into composites, these materials can achieve even higher thermal thresholds, making them suitable for the most demanding applications.

- Oxidation Resistance: Hafnium composites are highly resistant to oxidation, maintaining their integrity and performance even in oxidative environments. This property is crucial for applications involving high temperatures where oxidation could otherwise degrade the material.

- Thermal Stability: One of the standout properties of hafnium composites is their ability to retain mechanical properties at elevated temperatures. This thermal stability ensures durability and reliability in high-temperature applications.

- Strength and Hardness: These composites offer exceptional strength and hardness, critical for applications that require materials to be robust and resilient under extreme conditions.

Related reading: A List Of Heat-Resistant Materials

Types of Hafnium Composites

- Hafnium Carbide (HfC): Known for its extremely high melting point of approximately 3,900°C, hafnium carbide is often used in high-temperature ceramics and coatings. Its ability to withstand extreme temperatures makes it ideal for use in the aerospace and industrial sectors.

- Hafnium Diboride (HfB2): This ceramic composite is noted for its high thermal conductivity and excellent oxidation resistance. Hafnium diboride is commonly used in ultra-high-temperature applications, such as the thermal protection systems of hypersonic vehicles.

- Hafnium Nitride (HfN): With good electrical conductivity and thermal stability, hafnium nitride is used in electronics and as a high-temperature structural material. It is particularly useful in environments where both electrical and thermal performance are critical.

- Tantalum Hafnium Carbide (TaHfC): Among hafnium composites, tantalum hafnium carbide is particularly noteworthy. This material, a combination of tantalum, hafnium, and carbon, has an extraordinary melting point of approximately 3,988°C, making it one of the most heat-resistant materials known. Its applications include components for hypersonic vehicles, rocket nozzles, and parts in nuclear reactors.

Related reading: Tantalum Hafnium Carbide: Defying Extreme Conditions

Applications of Hafnium Composites

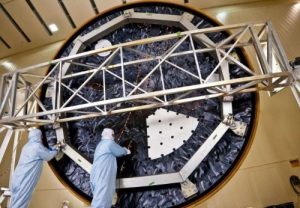

- Aerospace Industry: The aerospace sector heavily relies on hafnium composites for components exposed to extreme heat and stress. This includes parts for rockets, jet engines, and space vehicles. For instance, hafnium carbide and hafnium diboride are used in thermal protection systems and rocket nozzle linings, ensuring these components can withstand the intense heat generated during flight and re-entry.

- Nuclear Reactors: Hafnium composites are utilized in nuclear reactors due to their high thermal stability and neutron absorption capabilities. Hafnium's ability to absorb neutrons without forming long-lived radioactive isotopes makes it ideal for control rods and other reactor components.

- Industrial Furnaces: In industrial settings, hafnium composites are used for components and linings of furnaces that must endure prolonged exposure to high temperatures. Their durability and resistance to thermal degradation make them essential for processes such as metal smelting and high-temperature chemical reactions.

- Electronics: Hafnium nitride is employed in the electronics industry for applications that require materials to perform reliably at high temperatures. This includes use in high-temperature semiconductor devices and as coatings for electronic components.

Reported Cases and Studies

Recent studies and applications highlight the impressive capabilities of hafnium composites. For example, research conducted by NASA has demonstrated the effectiveness of hafnium diboride and tantalum hafnium carbide in protecting spacecraft from the extreme heat experienced during re-entry into the Earth’s atmosphere. These materials not only withstand the high temperatures but also provide the necessary structural integrity to ensure the safety and functionality of the spacecraft.

In a groundbreaking study, researchers from Imperial College London discovered that tantalum carbide and hafnium carbide materials can withstand temperatures of nearly 4,000 degrees Celsius. This study, published in Scientific Reports, found that hafnium carbide has the highest melting point ever recorded for a material, melting at 3,958°C. The research paves the way for these materials to be used in extreme environments, such as heat-resistant shielding for the next generation of hypersonic space vehicles. [1]

Scientists from the National University of Science and Technology (NUST) in Moscow fabricated a ceramic material, hafnium carbonitride, which demonstrated even higher heat resistance than hafnium carbide. Their innovative approach combined powdered hafnium and carbon, further combusted in a nitrogen atmosphere. The resulting material showed a melting point above 4,000°C, making it a promising candidate for high-temperature applications such as nose fairings, jet engines, and wings of hypersonic aircraft. [2]

Conclusion

Hafnium composites, the most heat-resistant materials, represent a pinnacle of material science innovation. Their unparalleled heat resistance, coupled with strength, hardness, and stability, makes them critical in pushing the boundaries of technology in some of the most challenging environments. As research and development continue, these materials will undoubtedly play an increasingly vital role in advanced industrial and scientific applications. Whether in the fiery ascent of a rocket or the controlled environment of a nuclear reactor, hafnium composites ensure performance and safety where it matters most.

Advanced Refractory Metals (ARM) provides an extensive selection of high-quality refractory metal products and heat-resistant materials. Our comprehensive inventory includes tungsten, molybdenum, tantalum, niobium, and rhenium, all meeting international standards to ensure consistency and suitability for various applications. For more information, please visit our homepage.

Reference:

[1] Brogan, C. (2016, December 22). New record set for world's most heat resistant material. Physics Organization. Retrieved May 14, 2024, from https://phys.org/news/2016-12-world-resistant-material.html

[2] Gasparini, A. (2020, May 31). Scientists Create World’s Most Heat Resistant Material With Potential Use For Spaceplanes. Forbes. Retrieved May 14, 2024, from https://www.forbes.com/sites/allisongasparini/2020/05/31/scientists-create-worlds-most-heat-resistant-material-with-potential-use-for-spaceplanes/?sh=36c3e7614f7e

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}