Get the Most Suitable Crucible for Your Lab

Introduction

Crucibles are essential components used in laboratories or research facilities where high-temperature processes are carried out. They are used to hold and heat samples or substances to very high temperatures for analysis, purification, or other applications.

Crucibles are made of various materials, including ceramics, glass, metals, and alloys, and come in different shapes and sizes. In this article, we will discuss how to choose the most suitable crucible for your lab. Hope that you can get the perfect crucible for your research.

Figure 1. Crucibles of Different Shapes

Material

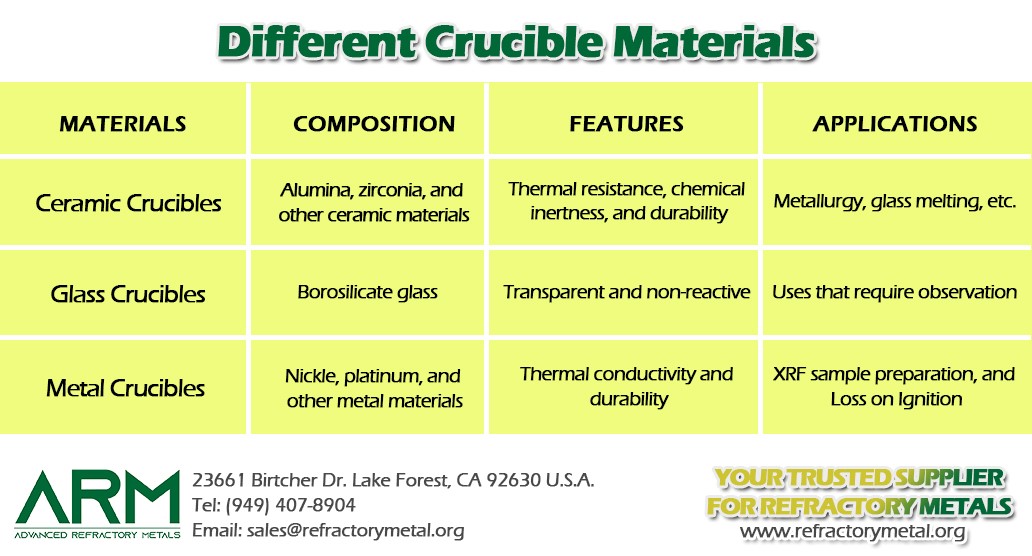

Let’s start by learning about the common crucible materials. Different materials have different properties that can affect the performance, durability, and suitability of the crucibles for specific applications.

- Ceramics: Ceramic crucibles are made of ceramics such as alumina, zirconia, and porcelain. They are known for their high-temperature resistance, chemical inertness, and durability. They are ideal for applications that involve corrosive chemicals, high-temperature reactions, and high-pressure conditions, such as metallurgy, gemstone purification, and glass melting.

- Glasses: Glass crucibles contain borosilicate glass, and they are transparent, non-reactive, and easy to clean, making them suitable for applications that require observation or visual monitoring of samples during heating or reaction.

- Metals: Metal crucibles composed of nickel, platinum, and tantalum stand out because of their high thermal conductivity and durability. They are applied to fields that involve high-temperature reactions and corrosive chemicals. Besides, platinum crucibles and other crucibles made of precious metals have become helpful tools used in XRF sample preparation and Loss on Ignition (LOI) recently.

Related reading: What Material Is A Crucible Made Of?

Size and Shape

The size and shape of the crucible are important factors to consider when choosing appropriate crucibles for your lab. The size of the crucible should be large enough to hold the sample or substance being heated, but not too large that it takes up unnecessary space in the furnace.

The shape of the crucible should be chosen based on the specific application or process being carried out. For example, a low-form crucible is ideal for evaporation and drying processes, while a high-form crucible works for heating and combustion processes. You can also choose between Bitumen crucibles, Gooch crucibles, and Rose crucibles. Advanced Refractory Metals (ARM) provides a variety of crucibles for your lab.

Figure 2. Low-form Tungsten Crucible

Others

Other factors to consider when choosing the most suitable crucible for your lab include the cost, availability, and compatibility with the furnace or heating equipment being employed. We should also consider the type of heating method being used, such as gas or electric, as this can affect the performance and durability of the crucible.

Take the case of platinum crucibles and their alloyed forms. They are high-performance crucible materials thanks to their heat resistance, chemical resistance, and durability.

- Gold-platinum crucibles are suitable for ash testing because this alloy has the best resistance to organic matter. You can choose platinum-iridium and platinum-rhodium crucibles as well.

- Platinum-iridium crucibles are highly resistant to corrosion and can withstand high temperatures, which makes them extensively used in evaporation and concentrating.

- Platinum-iridium is a high-temperature alloy. Also, it does not react with all acids and alkalis. Therefore, these crucibles are useful in the chemical industry for handling corrosive materials in high-temperature applications.

Conclusion

Choosing the most suitable crucible for your lab involves considering several factors, including the material, size, shape, and compatibility. It is crucial to choose a crucible that is durable, chemically inert, and suitable for the specific application or process being carried out. By carefully selecting the right crucible, you can ensure accurate and reliable results in your lab.

Advanced Refractory Metals (ARM) is a leading supplier of crucibles of different materials and shapes. There are ceramic crucibles, metal crucibles, and precious metal crucibles available. For more information, please check our homepage.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}