Recycling of Tungsten Tungsten is a kind of metal with a high melting point, and its melting point is the highest among all non-alloy metals. At the same time, tungsten is also very conductive, and it is often used to make tungsten wires. Tungsten is an important strategic metal. However, according to the current consumption rate, tungsten ore […]

Tags: Advanced Refractory Metals, ARM, metal with a high melting point, Recycling of Tungsten, refractory alloys, Refractory Metals, Tungsten, Tungsten Wires

Tungsten Alloys for Mobile Phone Motors Tungsten alloy is a kind of alloy based on tungsten (85% ~ 99% tungsten content) and added with a small amount of Ni. Cu, Fe. Co. Mo, Cr, and other elements. Its density is as high as 16.5 ~ 18.75g/ cm³. Thanks to their excellent properties, tungsten alloys are widely […]

Tags: Advanced Refractory Metals, ARM, Mobile Phone Motors, Refractory Metals, Tungsten, Tungsten alloys, types of refractory alloys, Types of Refractory Metals

Uses of Tungsten Alloy Wafers Tungsten alloy is an alloy composed of tungsten and other elements. A tungsten alloy wafer is a wafer made of tungsten-molybdenum alloy or tungsten thorium alloy or rare earth tungsten alloy or tungsten-rhenium alloy. It is often used as a substrate in power semiconductor devices and electric vacuum devices. It is […]

Tags: Advanced Refractory Metals, ARM, refractory alloys, Refractory Metals, Tungsten, Tungsten Alloy Wafers, Tungsten alloys, tungsten thorium alloy, tungsten-molybdenum alloy, Tungsten-rhenium alloy, Uses of Tungsten Alloy Wafers

Tungsten Copper Alloys for Motors As one of the key parts of the DC motor, the commutator segment can be made not only of silver-copper alloy but also of tungsten copper alloy. This is mainly due to the combination of the advantages of copper and tungsten in tungsten-copper alloys. That is, it has the characteristics of high strength, […]

Tags: Advanced Refractory Metals, ARM, Copper, permanent magnets, refractory alloys, Refractory Metals, Tungsten, Tungsten alloys, Tungsten Copper Alloys, Types of Refractory Metals

Uses of Tungsten Nickel Iron Alloys As a typical representative of high-density tungsten-based alloys, tungsten-nickel-iron alloys are widely used due to their higher density, smaller volume expansion coefficient, excellent plasticity, and weldability. Then in which areas can the alloy be used? In this article, let’s take a closer look at the uses of tungsten nickel-iron alloys. […]

Tags: Advanced Refractory Metals, ARM, refractory alloys, Refractory Metals, Tungsten, Tungsten alloys, Tungsten Nickel Iron Alloys, tungsten-nickel-iron

Tungsten Copper Alloy vs Tungsten Nickel Iron Alloy Tungsten-copper alloy, like tungsten-nickel-iron alloy, is a high-density tungsten alloy. But tungsten copper alloy vs tungsten nickel iron alloy, what’s the difference between them? If you looking for the answer to this question, then you’ve come to the right place. In this article, we will take a […]

Tags: Advanced Refractory Metals, ARM, powder metallurgy, refractory alloys, Refractory Metals, Tungsten alloys, Tungsten Copper, Tungsten Copper Alloy, Tungsten Nickel Iron Alloy, W-Cu alloy

Tungsten Copper Alloy for Electronic Packaging Materials Tungsten copper alloy (W-Cu alloy) is an alloy that combines the advantages of tungsten and copper. Specifically, it not only has the characteristics of high melting point, high density, and low expansion coefficient of metal tungsten but also good electrical and thermal conductivity properties of metal copper, so […]

Tags: Advanced Refractory Metals, ARM, Electronic Packaging Materials, refractory alloys, Refractory Metals, supplier of refractory alloys, supplier of refractory metals, Tungsten Copper Alloys, Tungsten Powder, W-Cu alloys

How to Improve the Performance of Tungsten Copper Alloy? Tungsten-copper alloy is an alloy composed of tungsten and copper. Commonly used tungsten copper alloys contain 10% to 50% copper. The alloy can be prepared by powder metallurgy and has good electrical and thermal conductivity, good high-temperature strength, and certain plasticity. In this article, we will introduce how to improve […]

Tags: Advanced Refractory Metals, ARM, Copper, Performance of Tungsten Copper Alloy, powder metallurgy, refractory alloys, Refractory Metals, Tungsten, Tungsten alloys, Tungsten Copper Alloys

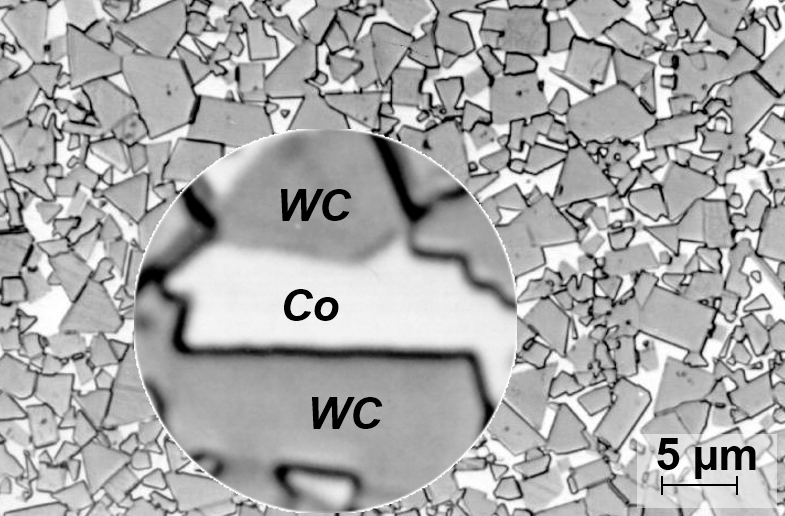

Magnetic Saturation and Coercivity of WC-Co Hard Alloys WC-Co hard alloy is an alloy with tungsten and cobalt as the main components. According to the cobalt content, WC-Co hard alloy can be divided into three types: high cobalt (20%~30%), medium cobalt (10%~15%), and low cobalt (3%~8%). This alloy can be used as a tool to process cast […]

Tags: Advanced Refractory Metals, ARM, Cemented Carbide, cobalt, Coercivity of WC-Co Hard Alloys, Magnetic Saturation of WC-Co Hard Alloys, manufacturer of refractory metals & alloys, supplier of refractory metals & alloys, Titanium alloys, Tungsten, Tungsten alloys, WC-Co Hard Alloys

Cemented Carbide for Watch Chains For the new generation of watch chains, the reason why cemented carbide should be used as the core raw material is that it has better wear resistance and the product is not prone to deformation under any circumstances. In this article, let’s take a quick look at the cemented carbide […]

Tags: Advanced Refractory Metals, ARM, Cemented Carbide, cobalt powder, manufacturer of refractory metals & alloys, refractory alloys, Refractory Metals, supplier of refractory metals & alloys, tungsten carbide, tungsten product

Copyright © 1994-2024 Advanced Refractory Metals owned by Oceania International LLC, All Rights Reserved.